![]() Tell Abraq axe with epigraph (‘tulip’ glyph + a person raising his arm above his shoulder and wielding a tool + dotted circles on body) [After Fig. 7 Holly Pittman, 1984, Art of the Bronze Age: Southeastern Iran, Western Central Asia, and the Indus Valley, New York, The Metropolitan Museum of Art, pp. 29-30].

Tell Abraq axe with epigraph (‘tulip’ glyph + a person raising his arm above his shoulder and wielding a tool + dotted circles on body) [After Fig. 7 Holly Pittman, 1984, Art of the Bronze Age: Southeastern Iran, Western Central Asia, and the Indus Valley, New York, The Metropolitan Museum of Art, pp. 29-30]. tabar = a broad axe (Punjabi).

Rebus: tam(b)ra ‘copper’ tagara ‘tabernae montana’, ‘tulip’. Rebus: tagara ‘tin’. Glyph: eṛaka ‘upraised arm’ (Tamil); rebus: eraka = copper (Kannada)

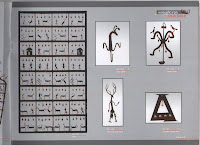

![]() h1522 Potsherd (from Indus Writing corpora) Note: The first known examples of writing may have been unearthed at an archaeological dig in Harappa, Pakistan. So-called 'plant-like' and 'trident-shaped' markings have been found on fragments of pottery dating back 5500 years. According to Dr Richard Meadow of Harvard University, the director of the Harappa Archaeological Research Project, these primitive inscriptions found on pottery may pre-date all other known writing. The glyph may denote tagaraka'tabernae montana' wild tulip. http://news.bbc.co.uk/2/hi/science/nature/334517.stm

h1522 Potsherd (from Indus Writing corpora) Note: The first known examples of writing may have been unearthed at an archaeological dig in Harappa, Pakistan. So-called 'plant-like' and 'trident-shaped' markings have been found on fragments of pottery dating back 5500 years. According to Dr Richard Meadow of Harvard University, the director of the Harappa Archaeological Research Project, these primitive inscriptions found on pottery may pre-date all other known writing. The glyph may denote tagaraka'tabernae montana' wild tulip. http://news.bbc.co.uk/2/hi/science/nature/334517.stm

So, the race is on to find the world's oldest writing. My suggestion is that Harappan find represens the world's oldest writing system. There is evidence of the system in Indus Writing Corpora of nearly 7000 inscriptions, presented in Indian Writing in Ancient Near East (Kalyanaraman, 2012).

Archaeo-metallurgical studies exemplified by Chakrabarti and Lahiri (Chakrabarti, D. K., and N. Lahiri 1996 Copper and its Alloys in Ancient India. Munshiram Manoharlal Publishers, New Delhi.) have been complemented by Lloyd R. Weeks which is a remarkable delineation of the Tin Road of the early Bronze Age. This monograph draws substantially from Weeks' thesis.

Meluhha contributions to the Bronze Age: lost-wax casting technique and tin-bronze, both evidenced by Meluhha hieroglyphs (Indus writing): dhokra, 'lost-wax casting' and ranku dhatu'tin ore'.

The conclusions by Weeks on the role of Meluhhans along the Tin Road are substantiated by the rebus readings of Meluhha hieroglyphs related to tin and alloys.

• ran:ku = tin (Santali)

• ran:ku = liquid measure (Santali)

• ran:ku a species of deer; ran:kuka (Skt.)(CDIAL 10559).

• dāṭu = cross (Te.); dhatu = mineral (Santali)

• Hindi. dhāṭnā ‘to send out, pour out, cast (metal)’ (CDIAL 6771).

These two hieroglyphs were inscribed on two tin ingots discovered in port of Dor south of Haifa from an ancient shipwreck. They are allographs. Both are read in Meluhha (Mleccha) of Indian sprachbund: ranku ‘liquid measure’; ranku ‘antelope’.Rebus: ranku ‘tin’. An allograph to denote tin is: tagara ‘ram’ Rebus: tagara ‘tin’. Rebus: damgar ‘merchant’ (Akkadian)

tagara ‘ram’ Rebus: tagaram ‘tin’. Ta. takar sheep, ram, goat, male of certain other animals (yāḷi, elephant, shark). பொருநகர் தாக்கற்குப் பேருந் தகைத்து (குறள், 486).Ma. takaran huge, powerful as a man, bear, etc. Ka. tagar, ṭagaru, ṭagara, ṭegaru ram. Tu. tagaru, ṭagarů id. Te. tagaramu, tagaru id. / Cf. Mar. tagar id. (DEDR 3000).Rebus 1: tagromi 'tin, metal alloy' (Kuwi) takaram tin, white lead, metal sheet, coated with tin (Ta.); tin, tinned iron plate (Ma.); tagarm tin (Ko.); tagara, tamara, tavara id. (Ka.) tamaru, tamara, tavara id. (Ta.): tagaramu, tamaramu, tavaramu id. (Te.); ṭagromi tin metal, alloy (Kuwi); tamara id. (Skt.)(DEDR 3001). trapu tin (AV.); tipu (Pali); tau, taua lead (Pkt.); tū̃ tin (P.); ṭau zinc, pewter (Or.); tarūaum lead (OG.); tarvũ(G.); tumba lead (Si.)(CDIAL 5992).Rebus 2: damgar ‘merchant’.

tagaraka tabernae montana (Skt.) Rebus: tagara ‘tin’ (Ka.)

ranku ‘antelope’Rebus: ranku = tin (santali)

tagara ‘ram’ Rebus: tagaram ‘tin’.

ranku ‘liquid measure’. Rebus: ranku ‘tin’ (Cassiterite) (Santali) ranga = tin (Kur.)

ayo ‘fish’ Rebus: ayo, ayas ‘metal. + tagara 'ram' on an anthropomorph:

Fish sign incised on copper anthropomorph, Sheorajpur, upper Ganges valley, ca. 2nd millennium BCE, 4 kg; 47.7 X 39 X 2.1 cm. State Museum, Lucknow (O.37) Typical find of Gangetic Copper Hoards.

The epigraphs incised on the ingots read as hieroglyphs, depict the nature of the property items: metallic tin (ranku dhātu) read rebus in mleccha (meluhha, milakkhu), the lingua francaof the bronze-age civilization linguistic area (Indian sprachbund).

dāṭu X rebus: dhatu ‘mineral’. The notch subscripted to X is a hieroglyph: खांडा khāṇḍā m A jag, notch, or indentation (as upon the edge of a tool or weapon). Rebus: khāṇḍā‘tools, pots and pans, metal-ware’. खुंट [ khuṇṭa ] The square or area formed by the meeting of four roads; An end or a point of a street or road. Commbined with āra‘brass’ as in ārakūṭa ‘brass’ (Skt.) Rebus: khū̃ṭ ‘community, guild’ (Mu.); kunḍa ‘consecrated fire-pit’. Rebus: खोट [ khōṭa ] an ingot or wedge or old metal melted down (Marathi) The X khuṇṭa may indicate that the tin ingot is for ‘alloying’ kūṭa. Thus, the message is ‘rub -- alloying mineral’ for tools, pots and pans, metalware, khāṇḍā

[The first sign from the left in Figure 4 compares with Sign 278 of Harappan (also called Indus script or Sarasvati hieroglyphs) in Daniels and Bright (1996: 167). This second pictograph incised on tin ingot 1, clearly is a stylized representation of an antelope as depicted on the Mohenjodaro copper plate inscription: The third sign, the X, seems to be more than merely an X; it is comparable to a variant of Sign 142 shown in Harappan.]

At this stage, a note on the orientation of the symbols is apposite. The two tin ingots have two signs written top to bottom, while normally Harappan writing is usually written from right to left. However, there are instances in the corpus of Harappan (Indus Script) epigraphs where the orientation of writing is top to bottom or even from left to right as on the Dholavira sign-board.

Map of Asia showing archaeological sites, metallurgical sites and ore deposits (After Fig. 8.1 in Lloyd R. Weeks, 2003).

A Sumerian merchant's account of the trade of tin and other metals

"Buying and selling metals in commerce can now be documented continuously from the latter half of the third millennium through the Old Babylonian period. Sumerian and Babylonian merchants went to Dilmun to buy copper and tin, while traders from Dilmun came to Mesopotamia, for example, to Sargonic Umma, Lagash, and Agade, as well as to Susa when it was under Sargonic rule. Contacts between Dilmun and archaic Uruk push the possibilities of such contact back half a millennium, while contacts with north Syria at various times extend the geographical horizon of such trade far beyond Sumer ... As the evidence accumulates, the continuity of this trade is impressive in its consistency." (Foster, B.1997, A Sumerian merchant's account of the Dilmun trade. Acta Sumerologica Japonica 19: 59).

Third millennium tin, tin-bronze trade controlled by Meluhhans

"T.F. Potts (1994:281) has suggested that the distribution of tin in third millennium western Asia was controlled by the Meluhhans. This hypothesis is based upon the pattern of early tin-bronze use in the region, and particularly its dearth in highland Iran, which Potts sees as reflecting differential access to maritime trade through the Gulf. Certainly the archaeological evidence for contact between southeastern Arabia and the Indus Valley indicates that Meluhhan tin and tin-bronze might have been accessible to the inhabitants of southeastern Arabia. However, the review of the archaeological evidence for foreign material in Magan suggests that central Asian tin and tin-bronze could also have been traded to southeastern Arabia via Iran or Baluchistan...In short, an Indus origin for the tin used in the Gulf region, and perhaps also in south-western Iran, seems the most likely situation."(pp.185-186)

Souther-maritime Tin Route

"If tin was in fact coming to Mesopotamia from the Indo-Iranian borderlands, we must imagine that it was either not traded through central and eastern Iran, or that when it was, none was utilized in local metal industries. Alternative routes to an overland Iranian Plateau trade include a southern trade through the Gulf, or a northern route across the Caspian Sea. The possibility of a southern tin and tin-bronze trade through the Gulf is supported by the results of the present study, although the absence of analyzed third millennium BCE objects from the central Gulf is still a significant lacuna

in our knowledge. As discussed above, such a trade route could explain the known distribution of tin bronze in southern Mesopotamia and at Susa, and indeed this has been proposed by T. F. Potts (1994:281).Of course, once tin and tin-bronze reached Mesopotamia, they could have been further dispersed to the west (i.e. the Troad and the Aegean) via overland trade through Anatolia. The higher tin-bronze frequency in the Troad than in central Anatolia is not a significant stumbling block to an overland trade hypothesis, if one regards the trade as directed more towards some consumers than others, rather than being simple down-the-line exchange."(p.193)

Potts, T.F., 1994, Mesopotamia and the East. An archaeological and historical study of foreign relations ca. 3400-2000 BCE. Oxford Committee for Archaeology Monograph 37. Oxford Committee for Archaeology, Oxford.

Words for tin and defining the Tin Road from Meluhha through Assur to Fertile Crescent

Mesopotamian EDI cuneiform texts from Ur distinguish between copper (urudu/eru) and tin=bronze (zabar/siparru). ED II/III texts from Fara (Limet 1960) mention metallic tin (AN.NA/annakum). Texts from Palace G at Ebla refer to the mixing of various ratios of 'washed' copper (a-gar(-gar)/abaru) and tin to produce bronze (Waetzoldt and Bachmann 1984; Archi 1993). The recipes are also found in the late 19th century BCE texs from Mari (Muhly 1985:282). Typical copper-tin ratios are from 6:1 to 10:1.

Archi, A., 1993, Bronze alloys in Ebla. In Between the Rivers and Over the Mountain. Archaeologica Anatolica et Mesopotamica alba Palmieri Dedicata, edited by M. Frangipane, H. Hauptmann, M. Liverani, P. Matthiae, and M. Mellink, pp. 615-625. Dipartimento di Scienze Storiche Archaologiche e Anthropologiche dell'Antichita Universita di Roma 'La Sapienza', Rome.

Limet, H., 1960, Le travail du metal au pays de Sumer au temps de la IIIe dynastic d'Ur, Les Belles Lettres, Paris.

Muhly, JD, 1985, Sources of tin and the beginnings of bronze metallurgy, American Journal of Archaeology, 89: 275-291.

Waetzoldt, H., and HG Bachmann, 1984, Zinn- und Arsenbronzen in den Texten aus Ebla und aus dem Mesopotamien des 3. Jahrtausends. Oriens Antiquus 23.

Two collections of cuneiform texts from Kultepe and from Mari dating to 19th and early 18th centuries BCE have references to tin trade. "These texts document a trade in which tin was moving exclusively from east to west. Arriving in Mesopotamia from the east, metallic tin was transhipped up the Euphrates to Mari, or overland to Assur. From Assur the tin (in addition to Babylonian textiles) was transported via donkey caravan to various Assyrian trading colonies such as Kanesh/Kultepe in Anatolia, where it was traded for silver and gold (Larsen 1976, 1987). From Mari, the tin was traded further west to sides in Syria and Palestine (Dossin 1970; Malamat 1971), and perhaps as far as Crete (Malamat 1971:38; Muhly 1985:282)." (p.179)

Dossin, G., 1970, La route de l'etain en Mesopotamie au temps de Zimri-Lim. Revue D'Assyriologie 64: 97-106.

Larsen, MT, 1976, The old Assyrian city-state and its colonies, Akademisk Forlag, Copenhagen.

Malamat, A., 1971, Syro-Palestinian destinations in a Mari tin inventory. Israel Exploration Journal 21:31-38.

Muhly, JD, 1985, Sources of tin and the beginnings of bronze metallurgy, American Journal of Archaeology, 89: 275-291.

Hypothesis of an eastern source for tin; epic tale of Enmerkar and Lord of Aratta

"One text from the reign of Gudea of Lagash mentions that, in addition to lapis lazuli and carnelian, tin was also traded to Mesopotamia from the land of Meluhha. The relevant passage (Cylinder B, column XIV, lines 10-13) states that 'Gudea, the Governor of Lagash, bestowed as gifts copper, tin, blocks of lapis lazuli, [a precious metal] and bright carnelian from Meluhha. (Wilson 1996; see also Muhly 1973: 306-307). This is the only specific cuneiform reference to the trade of tin from Meluhha...'A pre-Sargonic text from Lagash published by B. Foster (1997) and described as 'a Sumerian merchant's account of the Dilmun trade' mentions obtaining from Dilmun 27.5 minas (ca. 14 kg) of an-na zabar. This phrase can be literally translated as 'tin bronze', and Foster suggested the possible reading 'tin (in/for?) bronze'...The fact that the isotopic characteristics of the Aegean tin-bronzes are so similar to those from the Gulf analyzed in this study adds further weight to the hypothesis of an eastern source for these early alloys...The possibility of tin coming from these eastern sources is supported by the occurrence of many tin deposits in modern-day Afghanistan, Uzbekistan and Tajikistan, although evidence for tin extraction is currently limited to the central Asian sites of Karnab and Mushiston, and goes only as far back as the second millennium BCE...Yener has argued cogently against a 'on-source-for-all' model of the third millennium tin trade, and does not regard the proposed tin mining and processing in the Taurus Mountains as inconsistent with the importation of large amounts of tin into Anatolia. Taurus in production is thought to have co-existed with large-scale exchange of foreign metal in the third millennium, before the eventual 'devastation' of Anatolian tin mining operations by the availability of 'purer, already packaged, readily-available tin' from the Old Assyrian trade (Yener 2000:75)...IN particular, for regions such as Baluchistan, the Indus Valley, and the Gulf, which show significant third millennium tin-bronze use, the exclusive use of tin or tin-bronze from Afghanistan and central Asia seems highly likely. Textual sources are scarce, but highlight the trade through the Gulf linking Mesopotamia with Meluhha, Magan and Dilmun as the most common source of tin in the latter third millennium BCE, after an earlier overland Iranian tin-lapis-carnelian trade hinted at by the epic tale of Enmerkar and the Lord of Aratta. " (pp.180-181)

Muhly, JD, 1973, Copper and tin. Transactions, The Connecticut Academy of Arts and Sciences 43: 155-535.

Wilson, EJ, 1996, The Cylinders of Gudea. Transliteration, Translation and Index: Burzon and Bercker, Kevelaer.

Yener, K.A., 2000, The domestication of metals. The rise of complex metal industries in Anatolia. Culture and History of the Ancient Near East Volume 4, Brill, Leiden.

"Tin deposits occur in a number of Indian provinces, including Maharashtra, Karnataka, Bihar, Rajastan, and Gujarat (Chakrabarti and Lahiri 1996:25-26 and Map 2; Asthana 1993:278). Hegde (1978:40-41, Figure 2) further notes the possibility of alluvial cassiterite deposits in the Kaptagod, Aravalli and Chota Nagpur Hills, and more recent research in Haryana has identified a significant tincopper deposit at Tosham (also called "Tusham"; see Seetharam 1986; Kochhar et al. 1999; Chakrabarti 2002). The Hazari Bagh deposits of Bihar are the largest in India (Penhallurick 1986:21), while the smaller sources in Rajastan and Gujarat (and now at Tosham) have been regarded as more significant for early metallurgy due to their proximity to the Indus Valley (Asthana 1993:278). There is very little archaeological evidence for the early exploitation of these deposits, although Chakrabarti and Lahiri (1996:25-26) have drawn attention to British colonial descriptions of pre-industrial cassiterite extraction at Bastar in Madhya Pradesh, and Paharsingh and Nurungo in Bihar. Muhly (1985a:283), though allowing for the occurrence of significant alluvial cassiterite deposits in Madhya Pradesh, states his belief that Indian tin deposits are likely to have been an important source only for local metallurgy. Certainly, there is no strong archaeological evidence

for the exploitation of Indian tin sources in the Bronze Age, but the same can be said for copper mining in the region, which was almost certainly taking place by the third millennium BCE (Chakrabarti and Lahiri 1996:192-196)." (p.172)

Copper alloys

40 percent of objects analysed from Umm al-Nar Period were tin bronzes containing more than 2% tin. “There is archaeological evidence from the very end of the third millennium BCE that metallic tin was reaching southeastern Arabia, as the tin ring from Tell Abraq testifies...A number of Mesopotamian textual sources from the third and early second millennia BCE indicate that the movement of tin through the Gulf, and mention tin from Meluhha, Magan, and Dilmun...” (p.124)

“In theanalyzed assemblages from Umm al-Nar Period southeastern Arabia, the most common alloy types are pure copper (which contains less than one percent of arsenic, nickel, zinc and lead, and less than two percent tin), tin-bronze (copper with more than two percent tin), arsenical copper (copper with more than one percent arsenic), and nickel copper (copper with more than one percent nickel). The last two alloy types are commonly grouped together under the label As/Ni-copper, which includes all copper samples with more than one percent of arsenic and/or nickel.” (p.5)

Locus: Meluhha

“Almost all the third millennium BCE cuneiform texts from southern Mesopotamia which mention specific toponyms as copper sources speak of copper from either Magan or Dilmun (T. F. Potts 1994:Table 4.1). Meluhha, the third polity of the Lower Sea, is mentioned only rarely as a copper supplier, and then for amounts of only a few kilograms (Leemans 1960:161). The common association of Meluhha with the supply of carnelian, lapis lazuli, gold, precious woods, and especially ivory, suggests that the toponym is to be

related to the region between the Makran coast and Gujarat, encompassing sites of the Indus civilization (Heimpel 1993).” (p.15)

“The broader archaeological issue of the Bronze Age tin trade is also investigated in detail. The trade in this metal linked vast areas of western Asia, from the Indo-Iranian borderlands to the Aegean, through a series of overland and maritime trade routes and exchange relationships that are only hazily understood.”(From the Preface in: Weeks, Lloyd R., 2003, Early metallurgy of the Persian Gulf –Technology, trade and the bronze age world, Brill Academic Publishers, Boston, p.ix).

“Mesopotamia, as has often been stated, lacked resources. Its lack of metal ores required this world, at times, independent city-states and, at other times, empire, to look to distant lands in order to procure its metal/ores. Mesopotamian technology, however, was not a form of administrative or scribal concern. When it came to metal technology written texts offer limited information and are all but silent on the training, organization, and recruitment of metal smiths. Similarly, the texts are vague, or more typically silent, as to the geographical provenience from whence they obtained their metal/ore, its quantity, quality, price, or techniques of fabrication. It is left to the archaeologist and the recovered metal artifacts, workshops, associated tools, and mines, to address these questions...Decades ago VG Childe placed metallurgy on the top of his list of important crafts. He maintained that the development of early civilizations was a consequence of the invention of metallurgy (Childe 1930). Bronze-working, he believed, encouraged the manufacture of tools, which in turn led to more productive agriculture, and the growth of cities. Seventy-five years ago, Childe (1930:39) could point out that ‘Other documents from Mesopotamia, also written in the wedge-like characters called cuneiform, refer to the importation of copper from the mountainous region east of the Tigris and of metal and stones from Magan (probably Oman on the Persian Gulf)”…(Lloyd Weeks) introduces us to a new corpus of metal artifacts from the United Arab Emirates. Surprisingly, a significant percentage of these metals, recovered from the site of Tell Abraq, are tin-bronzes…his volume offers an up-to-date review of the enduring ‘tin-problem’ within the context of the greater Near East. Again, Childe (1928: 157) confronted the problem: ‘The Sumerians drew supplies of copper from Oman, from the Iranian Plateau, and even from Anatolia, but the source of their tin remains unknown’…(Lloyd Weeks) states ‘…the absolute source of the metal (tin-bronze) is likely to have been far to the north and east of Afghanistan or central Asia’. The central Asian source has been given reality by the recent discovery in Uzbekistan and Tadzhikistan of Bronze Age settlements and mines involved in tin production (Parzinger and Boroffka 2003).” (From CC Lamberg-Karlovsky’s Foreword in: Weeks, Lloyd R., 2003, Early metallurgy of the Persian Gulf –Technology, trade and the bronze age world, Brill Academic Publishers, Boston, pp. vii-viii).

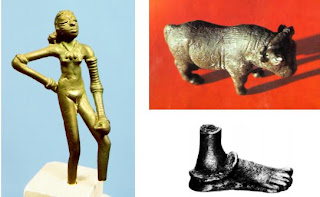

1,2 Large copper bull from Al-'Ubaid (T.O. 427). The hed is missing and has been restored in plaster on the basis of a companion piece (T.O 321) now in the British Museum. University Musum Collection: CBS 15886. Probably early third millennium BCE.

Bronze—an alloy of copper and tin—gave its name to one of the periods of antiquity. It is now clear that pure copper and other alloys of copper were also used during the Bronze Age in the Near East and eastern Mediterranean (roughly 3000-1200 B.C.), so the appellation cannot be considered strictly correct, But as a label it is still apt because bronze objects constitute the majority. Beyond the chronological distinction which the term Bronze Age implies lies the importance of the materials used in antiquity and the extent to which these materials have been important in the reconstruction of ancient lifestyles by archaeologists in the last 150 years. Materials in the form of artifacts and waste products are the tangible evidence of the activities and thoughts of ancient peoples and may be used in an attempt to recapture the past. We study materials with the goal of reconstructing the social and cultural systems in which they were produced and how ancient technology and technologists contributed to and were influenced by these systems.

![]()

3 Selected copper or bronze objects from Tepe Gawra, stratum VI, including knife, razor, pick-head, anklet and adze. Dropsie College Collection

4 Copper or bronze 'frying pan' from Tepe Gawra, stratum VI. University Museum Collection: 31-52-262.

5 Selected copper or bronze ornaments and implements from Tepe Gawra, including two pins, two serpents, tweezerrs, hairpin, bracelets and two toilet sets. The top three objects are from stratum V, the rest from stratum VI. University Museum Collection.

![]()

6 Necklace from Odoorn in the Dutch province of Drenthe, now in the Provincial Museum van Drenthe at Assen, ca 1400 BCE. The necklace is composed of pieces of amber, beads of faience and twenty-five beads of tin. (After L. Atchison (1960), A History of Metals, Vol. I, New York, Interscience: 81, Fig. 32).

7 Selected copper or bronze implements from Tepe Gawra, including sickles, axe, chisels and knife. The two needles are from Gawra stratum IV and the knife from stratum V; the other nine objects are from stratum VI. Gawra V-IV cover period ca 2100-1600 BCE; Gawra VI is second half of third millennium BCE. University Museum Collection.

8 Small copper or bronze deer head from Tepe Gawra, stratum VI. University Museum Collection: 31-52-270.

9 Nuggets of alluvial cassiterite, from the bed of a dry wadi at the site of Nuweibi in the Eastern desert of Egypt. This material, together with that illustrated in Fig. 10, was collected by Muhly, Rapp and Wertime in a trip to Egypt to be described in a forthcoming number of Expedition.

10 Piece of quartz containing inclusion of cassiterite, from site of El Mueilha in the Eastern Desert of Egypt.

11 Copper or bronze bowl and ewer from Sedment. Second Dynasty. University Museum Collection: E 15726, E 14244

12 Inscribed copper or bronze ewer with double spout, from the tomb of Pharaoh Khasekhemui at Abydos. Second Dynasty, early third millennium BCE. University Museum Collection: E9595

13 Model copper or bronze tools from Abydos (second, third, and fifth from left) and Beit Khallaf. First to Third Dynasties. University Museum Collection: E 9752, E 9404, E 9454, E 9740, E 9584.

The article attempts to give some indication of the rich collection of early metal objects in the University Museum. Much work remains to be done as we still know very little about the techniques of manufacture and the materials used. A long range program of analysis is now underway. All of these objects came into the collection as the result of excavations sponsored by the Museum in Iraq and Egypt, at such such sites at Tepe Gawr, Ur, Abydos and Gurob.

14 Copper or bronze adze (CBS 17419) and two axes (CBS 17512, 17913) from the Royal Cemetery at Ur, mid third millennium BCE. University Museum Collection.

15 Six copper or bronze spear heads from the King's Grave (PG/789) in the Royal Cemetery at Ur, mid third millennium BCE. University Museum Collection. No satisfactory explanation is known for the marking, attested on several objects from the Royal Cemetery. The excavator, Sir Leonard Woolley, thought that it might be a hallmark or even an owner's mark.

16 Sandstone mould for casting copper or bronze objects. From Tepe Gawra, stratum VI (second half of third millennium BCE) University Museum Collection: 31-52-164.

17 Copper or bronze saw from the Royal Cemetery at Ur, mid third millennium BCE. University Museum Collection: CBS 17367. A similar saw in gold was found in the grave of Queen Puabi (formerly read as Shubad).

18 Map showing major sites in the Near East

19a Ivory pyxis with tin lining found in a Mycenaean chamber tomb on the north slope of the Aeropagus, Athens. Ca 1400 BCE. The pyxis probably held cosmetics and the tin lining protected the ivory from being stained by the box's contents. Although no skeletal remains were found i the tomb, the pyxis and other objects (ivory barrettes, bronze mirror and cosmetic applicators among others) suggest that the occupant was a female.

![]()

19b Group of vases covered with tin foil from a Mycenaean chamber tomb on the north slope of the Areopagus, Athens, Ca 1350 BCE. The tin covering on the pottery may have been intended to give the appearance of silver, but tin itself was a valuable metal and its use suggests substantial wealth. Similar tin-covered vases have been found in the Argolid and Messenia in Greece and on Crete, Rhodes and Cyprus. The tin lining in the ivory pyxis and the use of tin to cover pottery show that metallic tin was available in Mycenaean Greece and used to an extent known in no other area of the eastern Mediterranean. We are arranging to obtain samples from the tin encrustations found on vases in Greece and Cyprus. (Reprinted after SA Immerwahr (1971) The Athenion Agoro--The Neolithic and Bronze Ages, Volume XIII, pl. 32 top and pl. 35 bottom, with permission of the Publications Office of the American School of Classical Studies at Athens.)

![]()

20 Tin bracelet from Thermi, level IV (mid third millennium BCE), on the Island of Lesbos. (Drawn by Andrew McGhie after Lamb 1936: 171, Fig. 50.)

22 One of the tin ingots dating to the Roman period, found in a shipwreck off Port-Vendres, France. (Drawn by Andrew McGhie after Colls, Domergue, Laubenheimer and Liou 1975: 64, Fig. 2.)

23 Tin ingots in the Museum of Ancient Art of the Municipality of Haifa, Israel (left #8251, right #8252). The ingots each bear two inscribed Cypro-Minoan markings. (Note: I have argued that the inscriptions were Meluhha hieroglyphs (Indus writing) denoting ranku 'tin' dhatu 'ore'. See: The Bronze Age Writing System of Sarasvati Hieroglyphics as Evidenced by Two “Rosetta Stones” By S. Kalyanaraman in: Journal of Indo-Judaic Studies Volume 1: Number 11 (2010), pp. 47-74.)

Metals differ from pottery in that the necessary raw materials are of limited distribution and so must be transported in response to needs of other communities.

Metalworking technology is more complicated than pottery production, with many people involved in the various phases of metallurgical endeavors, from extraction of ores to object manufacture. Metal objects are therefore less sensitive indicators of culture change on a local level, but are more productive than pottery in defining patterns of long-distance trade and the nature of transmission of ideas.

The two metals which make up bronze have been of interest to scholars for many years. The sources of copper and tin available to ancient metalworkers have been the subjects of much speculation, and it is now more or less agreed that the copper deposits of Cyprus, Turkey, Palestine and Iran were all important factors in Bronze Age metallurgy. Tin has proved more elusive because there are almost no geologically verified deposits in Southwest Asia or the eastern Mediterranean area. Because the origin of the tin used by ancient bronzeworkers cannot be pinpointed with accuracy, it has become the mystery metal of the ancient Near East. There are several lines of inquiry which should assist in locating tin sources and understanding the nature of the problem: geology and metallurgy, textual evidence and archaeological finds.

Most of the world’s tin deposits are hydrothermal, found in conjunction with granite or the granite family of rocks, Veins of tin running through granite, known as hard rock tin, were inaccessible to the ancient miner. In antiquity, tin stone or cassiterite (SnO2) was used. It is an oxide formed by weathering on the surface of the tin deposit, which was washed downstream in the form of nuggets which, because of their weight, were eventually deposited in the stream bed (see Charles 1975 for details). The best analogy for the activity of ancient miners in recovering stream tin is to the California ’49ers and their quest for alluvial gold. Like a gold stream, a tin stream can be panned out and leave no trace of its farmer contents. This situation certainly complicates the modern search for ancient tin sources, but there is hope in the fact that the host granitic formation will remain and the original tin lode may be identified,

The major tin sources in the world—Malaya, Indonesia, Thailand, China, Siberia, the Congo area and Bolivia—are far removed from the Mediterranean area and all except one are not known to have been exploited until after the time when tin bronze was being made in the Near East, shortly after 3000 B.C. The exception is Thailand where recent excavations [see Expedition 18, no. 4) at Non Nok Tha and Ban Chiang have shown a flourishing bronzeworking tradition which may predate the mid-fourth millennium B.C. The earliest analysed find from Ban Chiang—a dagger which dates to about 3600 B.C.contains 2.5% tin (determined by atomic absorption spectroscopy), a figure which indicates a deliberate alloy. By 3000 B.C., ancient metalsmiths in Thailand were producing good bronze with about a 10% tin content and were competently handling casting, coldworking and annealing. The early production of bronze in Thailand may eventually be found to have some relationship with the development of allaying techniques in the Near East. No artifacts of metallic tin have yet appeared in excavations in Thailand.

A major tin source is not of course necessary if a number of minor sources are available. Smaller tin deposits are found in areas much closer to the Near East than Thailand and deserve consideration. It should be repeated here that, although numerous Near Eastern tin sources have been cited in the literature, exploration in the Troad, Anatolia and Iran has failed to reveal any tin deposits (Muhly and Wertime 1973; Muhly 1976: 97-102). Recent geological research has shown that Egypt has significant tin reserves in the Eastern Desert, northeast of Aswan (Muhly 1976: 102-104). Hieroglyphic rock inscriptions testify to an Egyptian presence in the area in the Old Kingdom, but it is not yet known whether tin was recovered from this area in the third millennium. The Egyptians, in spite of a sophisticated metallurgy, did not alloy copper with tin until the second millennium, so if a case can be made for Bronze Age exploitation of the Eastern Desert tin it is most likely that it did not come until after 2000 B.C. An expedition consisting of Muhly, George Rapp and Theodore Wertime surveyed the area of tin deposits in December, 1976; at the time of writing the results of this work are not yet available.

In the Mediterranean basin, Tuscany and Iberia may be regarded as possible tin sources (Muhly 1973: 253-256), but there is no evidence that these deposits were worked during the Bronze Age. Bohemia is often cited as a passible tin source, but the deposits there are in veins of granite rock and therefore inaccessible to Bronze Age miners (Muhly 1976: 99-100). Tin also occurs in Cornwall but again it is not known whether it was recovered in the Bronze Age. In any case, northern and western tin deposits are inconsistent with the evidence of Near Eastern texts, in which tin is stated to come from the east (see below).

The smelting of tin from the oxide cassiterite with charcoal is fairly simple because of its low melting point (232°C). The smelted tin can then be added to smelted copper to produce bronze, Alternatively, copper ores and cassiterite ores could have been mixed before smelting and smelted together. This method might have produced alloys with variable tin percentages, although cassiterite is a high density ore containing almost 80% tin in most cases. Joint smelting may explain why few bronze objects have a tin content which reflects the 6:1 or 7:1 copper:tin ratio described in some Near Eastern texts. Co-smelting of copper and tin on a large scale is not likely because it would have required shipping tin ores to copper sources. Direct cassiterite additions to molten copper would not have produced a good bronze, since any amount of cassiterite in molten copper will result in only about a 1% tin content.

Tin as an alloying element in copper is superior to arsenic and zinc, metals also added to copper in antiquity. All three alloying elements make copper more fluid and thus easier to cast, but tin in a quantity of about 10% makes copper harder and stronger than arsenic and zinc additions. Tin also imparts greater corrosion resistance than zinc and arsenic, and reduces the melting point of copper from 1083°C to about 1020°C, for 10%; 5% arsenic reduces the melting point about 25°C, while zinc additions of 10% lower the melting point by about 30°C. An arsenic-copper alloy is darker and more satiny than pure copper, and zinc makes the copper more golden, while tin produces the characteristic bronze color. Tin must have been regarded as the superior alloying element because of the effort expended in obtaining it.

Various characteristics of tin are of interest to the archaeologist in terms of understanding its preservation and identification. The “tin pest” might explain in some areas the absence of recognizable artifacts of metallic tin. The tin pest is an allotropic modification in which tin changes from one form to another, i.e. goes from a white solid to a grayish powder, which in laboratory situations occurs at about 13.2°C. In reality, a much lower temperature is probably needed; the maximum velocity comes at -40°C. Even when the change has been started, the rate of transformation is slow. The “tin pest” is contagious, The special circumstances needed to develop the pest indicate that it is a factor in preservation in only a limited number of areas. The major recorded outbreak of tin pest illustrates the conditions under which it develops. When Napoleon’s army was retreating from Moscow in the bitterly cold winter of 1812, the tin buttons on the French uniforms started to disintegrate, leaving the flanks of the army more exposed than ever.

The “tin cry” provides a means of identifying tin in the field. If a small sliver of metal is removed from a tin artifact and twisted, it will produce an audible sound. The sound is produced by a shear movement of atom layers over other atom layers, which in tin occurs at very high speeds. Zinc is the only other metal that “cries,” but as far as we know it was not used in a metallic form in the Bronze Age. “Tin sweat” forms on the surface of cast bronzes when the liquid metal contains appreciable amounts of hydrogen which is released as a gas in a later stage of solidification. The gas forces tin-rich liquid, the last part of the copper-tin mixture to freeze, to the surface where it forms a silvery coating.

Sumerian An.Na and Akkadian anaku/ annaku mean tin and the meaning is now accepted by most scholars (for differing viewpoints see Eaton and McKerrell 1976: 179-182 and Kashkai 1976). The earliest references to tin and bronze come in the Sumerian texts from Fara which date to the middle of the third millennium B.C. Analytical work supports the textual evidence by establishing that tin bronze was being made in Mesopotamia at the same time (Moorey and Schweizer 1972: 180-185). The major textual evidence pertinent in a reconstruction of the tin trade comes from the early second millennium, in the tablets of Kiiltepe/Kanesh and Mari. Merchants from Assur brought tin in appreciable quantities to central Anatolia, implying that the latter area did not have its own sources of tin, at least in this period. But the texts do not tell us how the tin got to Assur and where it came from. It has generally been assumed that the tin came from northwestern Iran, although this is not explicitly stated and there is no geological evidence for tin in that area.

The tin itinerary from Mari, about a hundred years after the Kultepe Old Assyrian texts, adds to the list of distribution points but does not say much more about sources. Tin was shipped from Mari to such places as Aleppo, Qatna, Ebla, Layish (Dan), Hazor and ultimately to the “Kaptorite” in Ugarit. The involvement of this person in the tin trade—Kaptorite perhaps meaning Cretan—suggests the extent of the distribution of the precious metal. In this period Larsa and Sippar in southern Mesopotamia played important roles in the tin trade as points from which the tin was shipped to the north. Beyond southern Mesopotamia the tin route fades into obscurity, leaving us with the possibilities of Iran and the Persian Gulf as stations from which tin was shipped. Gudea of Lagash (22nd century B.C.) does state specifically that he used tin from the land of Meluhha. Unfortunately the location of Meluhha is not precisely known, but it is generally thought to indicate the Indus Valley civilization.

Ancient writers are oddly incurious about the source of the tin which they used in great quantity. In the Middle Assyrian period tin was used for paying fines and for paying interest on loans. Neo-Assyrian kings received enormous amounts of tin as tribute. It is obvious that a well-organized trade in tin supplied Mesopotamia from the third millennium onward, with some interruptions, and that Mesopotamia shipped tin to the west, same of which may have ended up as far away as Crete.

The rise of Mycenaean Greece may have been accompanied or even encouraged by the development of an alternate source of tin. Tin bronze and amber first appear in Greece in the Shaft Graves (ca 1600 B.C.) and are part of a complex of objects which suggest great wealth and the beginnings of organized political administration. There is now good evidence for trade in amber and tin between northern Europe and the British Isles, and some evidence for the extension of this trading pattern down the river valleys of Europe into the Mediterranean and the Adriatic. The Mycenaeans would not themselves have gone to northern Europe or the British Isles, but would have become prosperous by controlling the southern—presumably maritime—end of the trade route. There is no textual evidence from Mycenaean Greece to support this reconstruction, but that is not surprising since the Linear B tablets which mention metals describe only metalworkers and quantities of metal.

Although the Mycenaean evidence is not textual, it is important to place it beside the Near Eastern material. It is possible that, after 1600 B.C., tin came into the eastern Mediterranean area from two directions. Tin shipped from Greece was probably never an important factor in the literate Near East, so details of its trade and origin remain unknown. The major question related to tin being sold by Mycenaeans involves Cyprus: was intensive copperworking activity in Cyprus in the latter part of the Late Bronze Age related somehow to tin supplies being controlled by Mycenaeans, or can it be explained only on the basis of the variability of the archaeological record?

Although artifacts of metallic tin are rare, the metal was known to metalworkers in Mesopotamia, central Anatolia, the Troad and the Cyclades by the mid-third millennium B.C. when the first bronzes were made in these areas. Tin bronze may he several hundred years earlier in Tepe Yahya in southwestern Iran, a location where early bronze is not surprising in view of the later texts which describe tin as coming into Mesopotamia from the east.

Three objects of metallic tin which antedate 1200 B.C. appear in the archaeological record. The earliest is a bracelet made of one strip of tin twisted around a second from Thermi IV (W. Lamb 1936: Fig. 50; pl. XXV, 30-24). C. H. Desch found that the tin is pure with no copper, silver or lead and felt that the trace of iron which he detected probably came from the adhering earth (Ibid.: 215). Two tin objects from Egypt date to the late Eighteenth Dynasty (14th century B.C.). One is a pilgrim flask with hinged lid, now in the Ashmolean Museum (Ayrton et al. 1904: 50; pl. xvii, 20) and the second a fragmentary tin ring from Gurob (Petrie 1904: 19; pl. XXII, 10). The former is quoted as being made of “pure tin,” as is the latter which was analysed by Dr. Gladstone. The rarity of metallic tin finds has suggested in the past that ancient bronze-workers were not using smelted tin, but rather cassiterite ore. The 8 kg. of white material with the consistency of toothpaste found in the shipwreck off Cape Gelidonya, Turkey, might have forced a reconsideration of this hypothesis had its preservation not been so poor and the analysis more conclusive (Dykstra in Bass 1967: 171-172). By wet chemical analysis, the material was found to contain 71% calcium carbonate, some minor impurities and almost 14% tin. Dykstra suggests that the action of seawater had caused the tin to be replaced with calcium carbonate, but this chemical exchange seems unlikely. A second difficulty in interpreting this find as a tin ingot involves its color. Tin oxide is usually blackish, while the Gelidonya material was clearly white, although it is possible that immersion had somehow affected the characteristic oxide color of tin. The Gelidonya “tin” should be reanalysed before any definite conclusions about its identification can be reached.

The number of metallic tin objects known to us does not increase after 1000 B.C. Of interest is the cargo of a ship which sank in the Mediterranean off Port-Vendres, France between A.D. 20 and 50 (Coils et al. 1975). Fourteen tin ingots of a curious fenestrated type (for example Fig. 22) were distributed throughout the wreckage. The ingots vary in weight from slightly over 3 kg. to almost 9 kg. X-ray diffraction and atomic absorption analysis of twelve of the ingots showed them to be a pure tin with copper and lead present in only minute quantities. These ingots are particularly tantalizing because we have looked for their Bronze Age counterparts for years; the rarity of archaeological finds of tin ingots even in the Roman period when the extraction and trade in tin are fairly well documented is quite remarkable.

New Finds And New Perspectives

The rarity of the occurrence of tin means that it had to be shipped over great distances. It is unlikely to have been shipped as ore because ore has a greater bulk than a smelted metal. Therefore it was predicted that some

form of tin ingot must have been used in the Bronze Age. Indeed, blue or white ingots which have been identified as tin or lead appear in Egyptian tomb paintings with representations of copper oxhide ingots. The tin ingot hypothesis has been confirmed by the discovery of two tin ingots (Fig. 23), now in the Museum of Ancient Art of the Municipality of Haifa, Israel. We are greatly indebted to Dr. Yosef Elgavish, Director of the Museum, for his kindness in allowing us to study and remove samples from the ingots.

The ingots are roughly rectangular and have trapezoidal sections. They are 31.4 cm. and 32.4 cm. long, 19.0 and 21.6 cm. wide and 3.7 and 3.6 cm. thick, and weigh 11.4 and 11.9 kg. Each ingot has two signs engraved in the surface which are of Cypro-Minoan type, a script more popular in Cyprus than elsewhere and presumably indigenous to the island. The ingots were found by divers off the shore near Haifa and reportedly represent only a portion of a greater number of tin ingots. Further inquiries are now being made in Haifa to obtain more information about the location from which the ingots came and material that might have been associated with them.

A triangular wedge was removed with a hacksaw from the back upper left corner of each ingot for metallography and elemental analysis. The wedges are each about 1.0 cm. thick and 6.6 cm. and 4.5 cm. long. Drillings from the interior of each sample were submitted for elemental analysis by optical emission spectroscopy to determine which elements are present and by atomic absorption spectroscopy for more accurate quantitative determinations (Table 1). It is clear that the two ingots have substantially the same composition. There are some anomalies in the analyses which must be explained. The magnesium content can only be explained as originating from the sea since magnesium cannot be reduced in a charcoal smelting process. Magnesium is the second largest metallic constituent of seawater, so it is probably present in the form of magnesium salts. Other samples from the internal parts of the wedges have been submitted for neutron activation analysis, which, in spite of what appears to be internal corrosion (see below), should allow a more precise determination of the composition.

![]()

Few trace element analyses of tin sources and tin objects have been cited in the literature. Cobalt and germanium traces are identifying features of Cornish ores (Tylecote 1962: 63), but the Haifa ingots contain only cobalt and are thus probably not of Cornish origin. The two Egyptian tin objects and the bracelet from Thermi discussed above were determined to be “pure tin,” but the details of the analyses are not published. It may be possible to analyse the Egyptian objects again, but the Thermi bracelet seems to have disappeared in spite of great effort expended in locating it. The Roman tin ingots were analysed by atomic absorption for copper and lead (G. Perinet in Coils et al. 1975: 94) and show varying amounts of these two elements. Only one of these ingots (no. 10) is at all comparable to those from Haifa with 276 parts per million of copper opposed to 180 parts per million in the Haifa ingots. A more concerted program of elemental analysis by neutron activation is needed before any comparative judgments can be made about the metallic tin objects known from antiquity.

![]()

24 Optical photomicrograph of Haifa tin ingot 8251 showing a large grain size and black areas which represent the beginnings of corrosion. The smaller grains visible within the larger ones were caused by polishing X56 etched with a solution of 1 part nitric acid, 3 parts acetic acid and 5 parts glycerol.

In the case of pure tin, elemental analysis is more informative than metallographic study because tin is a soft metal and its structure may change in polishing it for microscopic study. A portion of the wedge taken from each ingot was polished, following standard metallographic procedures, and etched with a solution of one part nitric acid, three parts acetic acid and five parts glycerol. Examination with the optical microscope (Fig. 24) revealed a large grain size, indicating that the ingot had been slowly cooled. Black areas in the tin are probably the beginnings of corrosion, while the small grains which are visible within the large grains are artifacts of polishing. No second phase particles are visible, which would indicate the inclusion of impurities insoluble in tin, but it should also be considered that any second phase material might have been obscured by polishing. The presence of a second phase would reflect any unusual smelting conditions, which are unlikely to have occurred because the tin must have been smelted from a pure cassiterite ore.

Since the Haifa tin ingots do not come from a controlled archaeological context, the signs engraved on them are the only clue to their date. Two of the three signs (one sign is found on both ingots) are identifiable in the Cypro-Minoan syllabary (Masson 1974: 15: signs 95 and 102). The third and common sign is not known in the exact form it appears on the ingots, but it certainly-looks like a member of the same family. Cypro-Minoan script was used from the end of the sixteenth century B.C. to the end of the eleventh century, so the ingots must date to this period. Emilia Masson is studying the signs to determine whether their paleography will permit a closer dating.

The Cypro-Minoan signs on the Haifa tin ingots have important implications for metalworking and the metals trade in the Late Bronze Age. First, it is now clear that metallic tin was, in at least some cases, being used in bronze manufacture, rather than ores or master alloys with a high percentage of tin. Secondly, it is probable that both metals necessary in the making of bronze were distributed by an administrative complex centered on Cyprus. Although the source of the tin is unknown, it passed through Cyprus where it received the markings which are also found on some copper ingots of Late Bronze Age date. It is logical that copper and tin would have been shipped together, since they were to be used together. We do not know whether tin was already in ingot form when it arrived in Cyprus or whether imported ores were smelted on the island. Although the former seems more likely, the signs do not clarify the issue since they were engraved on the ingots after they were cast. Signs on oxhide ingots are in some cases part of the casting but on others subsequent engravings.

Cypro-Minoan script was also used extensively in Ugarit, which is therefore an alternate possibility for the immediate transshipment point of the Haifa ingots. It is nonetheless preferable to view Cyprus as the port of origin because the copper must have come from there, implying the existence of an effective mechanism of distribution of metals. Although the administrative organization was based on Cyprus, it does not help us to identify the administrators. Cyprus’ location and its role as an international emporium mean that it could have received tin from both the east and the west.

The Haifa ingots must have been part of a ship’s cargo. The ingots were loaded in Cyprus, or less likely in Ugarit, and shipped down to the Levantine coast, perhaps with a port in southern Palestine like Ashdod or even Egypt as a destination. The ship carrying the ingots finished its voyage near Haifa in an area known today as an ancient ship graveyard.

It has always been somewhat curious that oxhide ingots, except for one votive from Tell Beit Mirsim, are unknown from Palestine, since any shipping to Egypt would have passed along its coast and relations with Cyprus were close in the Late Bronze Age. The land has its own sources of copper and probably therefore did not participate in the ancient trade in Cypriote copper. But Palestine has no tin and, after the advantages of tin bronze over pure copper and arsenical copper were learned, would have needed to obtain tin from elsewhere. The Haifa ingots could indicate that the gap in Palestine’s natural resources was being filled by a Cypriote intermediary.