https://tinyurl.com/y6fp3zkq

The refrain of repeated occurrence of spoked wheel on Dholavira signboard is: eraka'nave of wheel' rebus arka'copper, gold', 'eṟaka, eraka any metal infusion; molten state' fusion (Kannada), eraka molten, cast (as metal); eraguni to melt (Tulu). dula'two' rebus dul'metal casting'. The key is lid hieroglyph ^ ḍhaṁkaṇa'lid' rebus dhakka'excellent, bright, blazing metal article'. Proclamation of metal artifacts, par excellence. Another key is 'claws of crab' hieroglyph: ḍaṭom, ḍiṭom to seize with the claws or pincers, as crabs, scorpions; rebus: dhatu 'mineral (ore)'.kanac 'corner' rebus: kañcu 'bronze'; loa 'ficus' rebus: loh 'copper, metal' PLUS karna 'ear'rebus: karna 'scribe' Smelters of ores, forgers of inscribed metal alloy wares.. What a proclamation of ca. 2500 BCE !!!

The refrain of repeated occurrence of spoked wheel on Dholavira signboard is: eraka'nave of wheel' rebus arka'copper, gold', 'eṟaka, eraka any metal infusion; molten state' fusion (Kannada), eraka molten, cast (as metal); eraguni to melt (Tulu). dula'two' rebus dul'metal casting'. The key is lid hieroglyph ^ ḍhaṁkaṇa'lid' rebus dhakka'excellent, bright, blazing metal article'. Proclamation of metal artifacts, par excellence. Another key is 'claws of crab' hieroglyph: ḍaṭom, ḍiṭom to seize with the claws or pincers, as crabs, scorpions; rebus: dhatu 'mineral (ore)'.kanac 'corner' rebus: kañcu 'bronze'; loa 'ficus' rebus: loh 'copper, metal' PLUS karna 'ear'rebus: karna 'scribe' Smelters of ores, forgers of inscribed metal alloy wares.. What a proclamation of ca. 2500 BCE !!!

See:

Unfolding of the discovery of Dholavira sign board. Proclamation of Bronze, alloy metalwork competence. https://tinyurl.com/y59y7bvh

Mehergarh, 5th millennium BCE. 2.2 cm dia. 5 mm reference scale. Perhaps coppper alloyed with lead. It is remarkable, that this six-spolked cire perdue copper alloy wheels made in Mehrgarh becomes a hieroglyph of Indus Script on Dholavira signboard.

I suggest that the so-called akṣa 'amulet' made in cire perdue (lost-wax) technique in Mehrgarh (5th millennium BCE) is NOT merely an amulet worn by the owner as a necklace tied to a string, but is a professional calling card, a proclamation in Indus Script hypertext writing, of Sarasvati Civilization early metalwork artisan's competence. Similarly, the Shahi Tump lead weight (4th millennium BCE) is not merely a signifier of weight standard of 15 kg. but a proclamation of accounting ledgers of wealth created by metalwork artisans of Sarasvati Civilization. This monograph posits that 1. the cire perdue copper alloy object is an Indus Script Hypertext to signify akṣaracaṇa 'scribe' (Kannada); and 2. Indus Script Hypertexts on the cire perdue copper alloy lead weight of Shahi Tump signify wealth accounting ledgers, metalwork catalogues.

The entire signboard proclamation is a hoarding to announce that the fortification is a smithy/workshop of a goldsmith:akkasāle, arkaśāla अर्क शाल m. (also written साल) , an enclosure , court , fence , rampart , wall (Inscriptions काव्य literature); mfn. (fr. शृ for श्रि) being in a house &c(

| शतपथ-ब्राह्मण)(Monier-Williams) |

![]() Sign 391 The hieroglyph together with

Sign 391 The hieroglyph together with ![]() Ka. cāṇa, cāna, cēṇa a small chisel. Tu. cēṇů, cēnů awl, chisel. Te. sēnamu id (DEDR 2445) is a Meluhha rebus rendering, a proclamation of akṣaracaṇa'scribe'.

Ka. cāṇa, cāna, cēṇa a small chisel. Tu. cēṇů, cēnů awl, chisel. Te. sēnamu id (DEDR 2445) is a Meluhha rebus rendering, a proclamation of akṣaracaṇa'scribe'.

As a hieroglyph/hypertext, akṣa signifies a wheel.अक्ष m. an axle , axis (in this sense also n.; a wheel , car, cart (Monier-Williams) Rebus: akṣa signifies a weight called कर्ष , equal to 16 माषs and also refers to an ancient coin called akkam, 1/12 of कर्ष (which is the root word for English 'cash').The pinnacle of achievement in Bronze Age Revolution relates to the invention of cire perdue technique of metal castings to produce metal alloy sculptures of breath-taking beauty. The quantum leap in knowledge systems occurred when the artifact was designed to signify in an Indus Script hypertext writing system, a goldsmith's workshop.

The Mehrgarh artifacts attempt to delineate the centre,middle of the wheel in the spoked-wheel copper alloy artifacts.

The suffix -caṇa in akṣaracaṇa 'scribe' signifies the centre,middle; क्षण the centre , middle (Monier-Williams)

चण mfn. ifc. ( Pa1n2. 5-2 , 26 ; = चञ्चु) renowned or famous for (हेमचन्द्र 's परिशिष्टपर्वन् viii , 195) cañcu चञ्चु a. [चञ्च्-उन्] 1 Celebrated, renowned, known. -2 Clever (as अक्षरचञ्चु); ओष्ठेन रामो रामोष्ठबिम्बचुम्बनचञ्चुता Śi.2.14; see चुञ्चु. -ञ्चुः 1 A deer. (Apte)

The spoked wheel made of copper alloy signifies akṣaracaṇa 'scribe'; and agasāle 'goldsmith, i.e. one who has a shop working with gold'.(Kannada)

śāˊlā f. ʻ shed, stable, house ʼ AV., śālám adv. ʻ at home ʼ ŚBr., śālikā -- f. ʻ house, shop ʼ lex.Pa. Pk. sālā -- f. ʻ shed, stable, large open -- sided hall, house ʼ, Pk. sāla -- n. ʻ house ʼ; Ash. sal ʻ cattleshed ʼ, Wg. šāl, Kt. šål, Dm. šâl; Paš.weg. sāl, ar. šol ʻ cattleshed on summer pasture ʼ; Kho. šal ʻ cattleshed ʼ, še li ʻ goatpen ʼ; K. hal f. ʻ hall, house ʼ; L. sālh f. ʻ house with thatched roof ʼ; A. xāl, xāli ʻ house, workshop, factory ʼ; B. sāl ʻ shed, workshop ʼ; Or. sāḷa ʻ shed, stable ʼ; Bi. sār f. ʻ cowshed ʼ; H. sāl f. ʻ hall, house, school ʼ, sār f. ʻ cowshed ʼ; M. sāḷ f. ʻ workshop, school ʼ; Si. sal -- a, ha° ʻ hall, market -- hall ʼ.(CDIAL 12414) शाला f. (ifc. also n(शाल).) a house , mansion , building , hall , large room , apartment , shed , workshop , stable AV. &c ([cf. Germ. saal ; Eng.hall])

The cire perdue spoked wheel of copper+lead alloy was NOT an amulet, it was a metal artifact, a metal coin, akkam; it was a compartmental Harappa seal with Harappa (Indus) Script hieroglyph. May or may not have been used as a coin to value and exchange goods but a proclamation of the metallurgical excellence achieved by Bharatam Janam of 4th millennium BCE and the invention of writing by akṣaracaṇa 'scribe' (Kannada) signified by the Mehrgarh spoked wheel amulet. I also suggest that the invention of the Indus Script Hypertext of a spoked wheel to signify a 'scribe' is an invention by a goldsmith, akkasāliga.(an expression derived from the root akṣa अक्ष m. an axle , axis (in this sense also n.); a wheel , car , cart [cf. Lat. axis ; Old Germ.ahsa ; Mod. Germ. Achse; Lith. assis.]; a weight called कर्ष , equal to 16 माषs (Monier-Williams) akṣḥ अक्षः [अश्-सः] 1 An axis, axle, pivot; अक्षभङ्गे च यानस्य....न दण्डं मनुरब्रवीत् Ms.8.291,292; दृढधूः अक्षः Kāś. V. 4.74; Śi.12.2, 18.7; ज्योतिश्चक्राक्षदण्डः Dk. 1 Axle-pole. -2 The pole of a cart. -3 A cart, car; also a wheel; -चक्रम् the circle of sensual passions. दृढनियमित ˚क्रः K.37 (also axis and wheels); -वाटः [अक्षाणां पाशकक्रीडानां बाटः वासस्थानम्] 1 a gambling house; the gambling table. -2 [अक्षस्य रथचक्रस्य क्षुण्णस्थानस्य इव वाटः] a place of contest, arena, wrestling ground (तत्र हि रथचक्रक्षुण्णपांशुसदृशपांशुम- त्त्वात् तत्सदृशत्वम् Tv.) -विदa. skilled in gambling. -वृत्त a. [अक्षे वृत्तः व्यापृतः स. त.] engaged in, addicted to, gambling; what has occurred in gambling (Apte) अक्ष m. an axle , axis (in this sense also n.; a wheel , car , cart (Monier-Williams).

अर्क m. ( √ अर्च्) , Ved. a ray , flash of lightning RV. fire RV. ix , 50 , 4; fire (शतपथ-ब्राह्मण; बृहद्-ारण्यक-उपनिषद्); the sun (RV). Rebus: अर्क a learned man (cf. RV. viii , 63 , 6) Rebus: अर्क copper; அருக்கம் ¹arukkam, n. < arka. (நாநார்த்த.) 1. Copper; செம்பு. 2.Crystal; பளிங்கு. S. I. I . ii. 123.)

akka-cālai *அக்கசாலை akka-cālai , n. < arka +. 1. Metal works; பொன் முதலிய உலோக வேலை செய்யு மிடம் . (சிலப் . 16, 126, உரை .) 2. Mint; நாணயசாலை . (W .)

Harappa (Indus) script hieroglyph: eraka 'knave of wheel' rebus: eraka '

agasāle, agasāli, agasālevāḍu <arka sAle= a goldsmith (Telugu)

అగసాలి agasāli or అగసాలెవాడు agasāli. [Tel.] n. A goldsmith. కంసాలివాడు.

![]() Kannada Glosses

Kannada Glosses

erka = ekke (Tbh. of arka) aka (Tbh. of arka) copper (metal); crystal (Kannada) cf. eruvai = copper (Tamil)

ákṣa1 m. ʻ axle ʼ RV., ʻ collar -- bone ʼ ŚBr., ʻ temporal bone ʼ Yājñ., akṣaka -- m.n. ʻ collar -- bone ʼ Suśr. [Perh. conn. ákṣu -- ]Pa. akkha -- m. ʻ axle ʼ, °aka -- m. ʻ collar-bone ʼ; Pk. akkha<-> m. ʻ collar-bone ʼ, KharI. akha -- ; Or. akha ʻ axle-tree ʼ; Bi. akhaut ʻ axle of grain -- husker ʼ, akhautā ʻ do. of brick -- crusher ʼ (+ ?); G. ã̄k m. ʻ axle ʼ, M. ās, ã̄s m. ʻ axle, temple of head ʼ (→ G. ã̄s m. ʻ axis ʼ), ã̄kh m. ʻ axle ʼ; Si. aka ʻ axle ʼ, akuva ʻ collar -- bone ʼ (< akṣaka -- Geiger GS 30).(CDIAL 21)*akṣakīla cf. akṣāgrakīla -- , °aka -- m. ʻ lynch -- pin ʼ lex. [ákṣa -- 1, kīla -- ]Bi. (Patna) akhailā ʻ axle of brick -- crusher ʼ.(CDIAL 26)akṣadhur f. ʻ pin or pole of axle ʼ. [ákṣa -- 1, dhúr -- ]M. ākhrī, akh° f. ʻ beam over the axle on which the frame of the cart rests ʼ; Si. akura ʻ axle of a wheel ʼ.(CDIAL 31)*akṣākāra ʻ shaped like a die ʼ. [akṣá -- 2, ākāra -- ]H. akhār m. ʻ a small lump of clay placed in the centre of a potter's wheel ʼ.(CDIAL 40) आस or आंस āsa or āṃsa m (अक्ष S) An axle. (Marathi)[quote]Bourgarit and Mille (Bourgarit D., Mille B. 2007. Les premiers objets métalliques ont-ils été fabriqués par des métallurgistes ? L’actualité Chimique . Octobre-Novembre 2007 - n° 312-313:54-60) have reported the finding (probably in the later still unreported excavation period) of small Chalcolithic “amulets” which they claim to have been produced by the process of Lost Wax. According to them, “The levels of the fifth millennium Chalcolithic at Mehrgarh have delivered a few amulets in shape of a minute wheel, while the technological study showed that they were made by a process of lost wax casting. The ring and the spokes were modelled in wax which was then coated by a refractory mould that was heated to remove the wax. Finally, the molten metal was cast in place of the wax. Metallographic examination confirmed that it was indeed an object obtained by casting (dendrite microstructure). This discovery is quite unique because it is the earliest attestation of this technique in the world.” They then, further on, state that “The development of this new technique of lost wax led to another invention, the development of alloys...Davey (Davey C. 2009.The Early History of Lost-Wax Casting, in J. Mei and Th. Rehren (eds), Metallurgy and Civilisation: Eurasia and Beyond Archetype, pp. 147-154. London: Archetype Publications Ltd.) relies only upon these Mehrgarh findings , as well as on the Nahal Mishmar hoard, to claim that Lost Wax casting began in the Chalcolithic period before 4000 BCE.” [unquote] (Shlomo Guil)

Six bronze stamps (a-b) circular with pin-wheel design recalling a svastika (c) square with heart-shaped pattern; broken lug on the back (d-f) broken with radiating spokes; one with broken lug. British Museum No.1880.3710.a-f

Curator's comments: IM.Metal.154. C. Fabrègues: Together with 1880.3710.b-c, the object belongs to the large class of compartmented seals. Such partitioned seals are characteristic of the Bactria-Margiana Archaeological Complex (BMAC, also known as the Oxus Civilization), the modern archaeological designation for a Bronze Age culture located along the upper Amu Darya (Oxus River) in present-day Turkmenistan, Afghanistan, southern Uzbekistan and western Tajikistan. The BMAC may have extended as far as southern Afghanistan and Baluchistan, which have also yielded artefacts typical of the culture. 'Six bronze stamps for impressing designs'. That is, these objects could also have served as seals to impress on objects produced for trade by metalworking artisans. Compartmented seals have been found in large numbers in these areas, both from clandestine diggings in the 1970s (Pottier 1984, Tosi 1988, fig.11, Salvatori 1988) and from scientific excavations. Known sites where examples have been excavated are: Namazga on the banks of the Murghab river (Masson and Sarianidi 1972) Togolok (Sarianidi 1990) and Gonur Tepe in Margiana (Sarianidi 1993, 2002), Dashly Tepe (Masson and Sarianidi 1972) and Mundigak (Casal 1961) in Afghanistan, Dabar Kot, Rana Gundai and Shahi Tump (Amiet 1977, p.117), and the Mehrgarh-Sibri complex (Sarianidi 1993, p.37) in Baluchistan. These seals depict geometrical motifs, like 1880.3710.a–c, and also floral motifs, crosses, animals such as goats, snakes and scorpions, birds (primarily eagles with spread wings), human figures and fantastic dragons. 1880.3710.a, c closely resemble some examples from plundered tombs in Bactria, now in the Louvre Museum (Amiet 2002, p.168, fig.13.h, l) and 1880.3710.c an example said to come from southern Bactria, now in a private collection (Salvatori 1988, p.183, fig.49, bottom right). Impressions of such seals have been found on pottery. Scholars disagree about their use. It has been suggested that they were used for administrative control of trade and production (Hiebert 1994, p. 380); were related to a well organised trade system which involved transporting and transacting goods over long distances (Salvatori 1988, p.163); were symbols of power and property, or, since a large number have similar images, they may have served as amulets protecting their owners from evil rather than as symbols of ownership (Sarianidi 2002, p.41). Compartmented seals have been variously dated to the end of the 3rd/beginning of the 2nd millennium (Amiet 1977, p.119, Salvatori 1988), or to the first half of the 2nd millennium BC (Tosi 1988, p.123, Sarianidi 1993, p.36). According to Amiet (1977, p.117, 1988, pp.166, 169), they originated in Iranian Sistan: at Shar-i-Sokhta their development can be charted throughout the 3rd millennium BC from steatite prototypes and it is only here and at Shahdad, on the other side of the Lut desert in the Kerman region, that they are known to have been used as marks on pottery (Hakemi and Sajjadi 1988, pp.145, 150). Sarianidi considers this a purely local invention (2002, p.41).The Begram seals add to the number of examples already available, provide an exact provenance for some varieties and evidence that the Begram plain had interaction with the BMAC."

http://www.britishmuseum.org/research/collection_online/collection_object_details/collection_image_gallery.aspx?assetId=297337001&objectId=179600&partId=1#more-views

Later, from Shahi Tump were recovered 'Shahi Tump amulets' and also another unique cire perdueobject made of copper and lead, called a lead-weight weighing 15 kg.

Shahi Tump Leopard weight of Shahi Tump (Balochistan), National Museum, Karachi. The artefact was discovered in a grave, in the Kech valley, in Balochistan. ca. 4th millennium BCE. 200 mm. h. 13.5kg wt. The shell has been manufactured by lost-wax foundry of a copper alloy (12.6% Pb, 2.6% As), then it has been filled up through lead (99.5%) foundry. The shell is engraved with figures of leopards hunting wild goats, made of polished fragments of shellfishes. No identification of the artefact's use has been given. (Scientific team: B. Mille, D. Bourgarit, R. Besenval, Musee Guimet, Paris. Source: https://www.academia.edu/8164498/Early_lost-wax_casting_in_Baluchistan_Pakistan_the_Leopards_Weight_from_

Shahi Tump. Kech valley, Makran division, Baluchistan, Pakistan (After Fig. 1 in Thomas et al)

Benoit Mille calls the bronze stamps of Shahi-Tump 'amulets' (made from copper alloyed with lead). Mehrgarh is well recognised

as a centre for early pyrotechnologies.The wax models of the stamps would have been solid and may have had a simple core inserted.This is perhaps the first stage in the technology:

"Small copper-base wheel-shaped “amulets” have been unearthed from the Early Chalcolithic levels at Mehrgarh in Balochistan (Pakistan), dating from the late fifth millennium B.C. Visual and metallographic examinations prove their production by a lost-wax process—the earliest evidence so far for this metalworking technique. Although a gap of more than 500 years exists between these ornaments from Mehrgarh and the later lost-wax casts known in the Indo-Iranian world, the technological and compositional links between these artefacts indicate a similar tradition. We already know that the lost-wax process was commonly used during the second half of the fourth millenium B.C, as exemplified by figurative pinheads and compartmented seals, the latter of which were produced and distributed across the region until the early second millennium B.C. Most, if not all, of these artefacts were made using the lost-wax technique. This intensive practice of lost-wax lasting certainly stimulated the technical development of the process, allowing the elaboration of more complex and heavier objects. The “Leopards Weight” (Balochistan, late fourth or early third millennium B.C.) is one of the best examples of these developments: the lost-wax copper jacket, with its opened hollow shape, constitutes an extraordinary technical achievement.(Mille, B., Bourgarit, D., and Besenval, R. 2005. 'Metallurgical study of the 'Leopards weight' from Shahi-Tump (Pakistan)', in C. Jarrige and V. Lefevre, eds., South Asian Archaeology 2001, Editions Recherches sur les Civilisations, Paris: 237-44) True hollow casting does not appear until the third millennium B.C., as illustrated by the manufacture of statuettes, including the Nausharo bull figurine (Balochistan, 2300–2100 B.C.), or those from BMAC sites in Central Asia (based upon analyses of items in the Louvre collections). The birth of the lost-wax casting process can also be paralleled with the first emergence of alloying in South Asia, as many of these early lost-wax cast artefacts were made of a copper-lead alloy (c. 10–40 wt% Pb and up to 4 wt% As). Significantly, it seems that the copper-lead alloy was solely dedicated to artefacts made using the lost-wax technique, a choice no doubt driven by the advantageous casting properties of such an alloy." (Mille, Benoit, On the origin of lost-wax casting and alloying in the Indo-Iranian world, in: Lloyd Weeks, 2007, The 2007 Early Iranian metallurgy workshop at the University of Nottingham)

https://www.academia.edu/3858109/The_2007_workshop_on_early_Iranian_metallurgy_at_the_University_of_Nottingham

https://www.academia.edu/3858109/The_2007_workshop_on_early_Iranian_metallurgy_at_the_University_of_Nottingham

Decipherment of Indus Script Hypertexts on Shahi Tump lead weight

Hieroglyphs of Indus Script Cipher are sitnified on the Shahi Tump leopard weight which has been produced using the lost-wax casting method. The hieroglyphs are: 1. leopard; 2. ibex or antelope; 3. bees (flies). The rebus-metonymy readings in Meluhha are:

karaḍa ‘panther’; karaḍa tiger (Pkt); खरडा [ kharaḍā ] A leopard. खरड्या [ kharaḍyā ] m or खरड्यावाघ m A leopard (Marathi). Kol. keḍiak tiger. Nk. khaṛeyak panther. Go. (A.) khaṛyal tiger; (Haig) kariyāl panther Kui kṛāḍi, krānḍi tiger, leopard, hyena. Kuwi (F.) kṛani tiger; (S.) klā'ni tiger, leopard; (Su. P. Isr.) kṛaˀni (pl. -ŋa) tiger. / Cf. Pkt. (DNM) karaḍa- id. (DEDR 1132).Rebus: करडा [karaḍā] Hard from alloy--iron, silver &c. (Marathi) kharādī ' turner, a person who fashions or shapes objects on a lathe' (Gujarati)

Hieroglyph: miṇḍāl 'markhor' (Tōrwālī) meḍho a ram, a sheep (Gujarati)(CDIAL 10120) Rebus: mẽṛhẽt, meḍ 'iron' (Munda.Ho.) mr̤eka, melh 'goat' (Telugu. Brahui) Rebus: melukkha 'milakkha, copper'. If the animal carried on the right hand of the Gudimallam hunter is an antelope, the possible readings are: ranku 'antelope' Rebus: ranku 'tin'.

Ka. mēke she-goat; mē the bleating of sheep or goats. Te. mē̃ka, mēka goat. Kol. me·ke id. Nk. mēke id. Pa. mēva, (S.) mēya she-goat. Ga. (Oll.)mēge, (S.) mēge goat. Go. (M) mekā, (Ko.) mēka id. ? Kur. mēxnā (mīxyas) to call, call after loudly, hail. Malt. méqe to bleat. [Te. mr̤ēka (so correct) is of unknown meaning. Br. mēḻẖ is without etymology; see MBE 1980a.] / Cf. Skt. (lex.) meka- goat. (DEDR 5087). Meluhha, mleccha (Akkadian. Sanskrit). Milakkha, Milāca ‘hillman’ (Pali) milakkhu ‘dialect’ (Pali) mleccha ‘copper’ (Prakritam).

The bees are metaphors for wax used in the lost-wax casting method.

mákṣā f., mákṣ -- m. f. ʻ fly ʼ RV., mákṣikā -- f. ʻ fly, bee ʼ RV., makṣika -- m. Mn.Pa. makkhikā -- f. ʻ fly ʼ, Pk. makkhiā -- f., macchī -- , °chiā -- f.; Gy. hung. makh ʻ fly ʼ, wel. makhī f., gr. makí f., pol. mačin, germ. mačlin, pal. mắki ʻ mosquito ʼ,măkīˊla ʻ sandfly ʼ, măkīˊli ʻ house -- fly ʼ; Ash. mačī˜ˊ ʻ bee ʼ; Paš.dar. mēček ʻ bee ʼ, weg. mečīˊk ʻ mosquito ʼ, ar. mučək, mučag ʻ fly ʼ; Mai. māc̣hī ʻ fly ʼ; Sh.gil.măṣīˊ f., (Lor.) m*l c̣ī ʻ fly ʼ (→ Ḍ. m*l c̣hi f.), gur. măc̣hīˊ ʻ fly ʼ (ʻ bee ʼ in gur. măc̣hi̯kraṇ, koh. măc̣hi -- gŭn ʻ beehive ʼ); K. mȧchi f. ʻ fly, bee, dark spot ʼ; S. makha,makhi f. ʻ fly, bee, swarm of bees, sight of gun ʼ, makho m. ʻ a kind of large fly ʼ; L. (Ju.) makhī f. ʻ fly ʼ, khet. makkīˊ; P. makkh f. ʻ horsefly, gnat, any stinging fly ʼ, m. ʻ flies ʼ, makkhī f. ʻ fly ʼ; WPah.rudh. makkhī ʻ bee ʼ, jaun. mākwā ʻ fly ʼ; Ku. mākho ʻ fly ʼ, gng. mã̄kh, N. mākho, A. mākhi, B. Or. māchi, Bi. māchī, Mth. māchī,mã̄chī, makhī (← H.?), Bhoj. māchī; OAw. mākhī, lakh. māchī ʻ fly ʼ, ma -- mākhī ʻ bee ʼ (mádhu -- ); H. māchī, mākhī, makkhī f. ʻ fly ʼ, makkhā m. ʻ large fly, gadfly ʼ; G. mākh, mākhī f. ʻ fly ʼ, mākhɔ m. ʻ large fly ʼ; M. mās f. ʻ swarm of flies ʼ, n. ʻ flies in general ʼ, māśī f. ʻ fly ʼ, Ko. māsu, māśi; Si. balu -- mäkka, st. -- mäki -- ʻ flea ʼ, mässa, st. mäsi -- ʻ fly ʼ; Md. mehi ʻ fly ʼ.

*makṣātara -- , *mākṣa -- , mākṣiká -- ; *makṣākiraṇa -- , *makṣācamara -- , *makṣācālana -- , *makṣikākula -- ; *madhumakṣikā -- .

Addenda: mákṣā -- : S.kcch. makh f. ʻ fly ʼ; WPah.kṭg. mákkhɔ, máṅkhɔ m. ʻ fly, large fly ʼ, mákkhi (kc. makhe) f. ʻ fly, bee ʼ, máṅkhi f., J. mākhī f.pl., Garh. mākhi. (CDIAL 9696) mākṣiká ʻ pertaining to a bee ʼ MārkP., n. ʻ honey ʼ Suśr. 2. *mākṣa -- . [mákṣā -- ]

1. WPah.bhad. māċhī ʻ bee ʼ, khaś. mākhī; -- Pk. makkhia -- , macchia -- n. ʻ honey ʼ; Ash. mači, mačík ʻ sweet, good ʼ, mačianá ʻ honey ʼ; Wg. mác̣i, mäc̣ ʻ honey ʼ, Kt. mac̣ī˜, Pr. maṭék, Shum. mac̣hī, Gaw. māc̣hī, Kal.rumb. Kho. mac̣hí, Bshk. mē̃c̣h, Phal. mn/ac̣hī, mḗc̣hī, Sh. măc̣hīˊ f., S. L. mākhī f., WPah.bhiḍ. māċhī n., H.mākhī f.

2. K. mã̄ch, dat. °chas m. ʻ honey ʼ, WPah.bhal. māch n. -- For form and meaning of Paš. māš, mōṣ ʻ honey ʼ see NTS ii 265, IIFL iii 3, 126.

*mākṣakulika -- , *mākṣikakara -- , *mākṣikamadhu -- .Addenda: mākṣika -- : Kho. mac̣hi ʻ honey ʼ BKhoT 70.(CDIAL 9989)*mākṣikakara or *mākṣakara -- ʻ bee ʼ. [Cf. madhu- kara -- m. ŚārṅgP., °kāra -- m. BhP., °kārī -- f. R. <-> mākṣiká -- , kará -- 1 ]

Ash. mačarīk, °čerīˊk ʻ bee ʼ, Wg. mac̣arīˊk, Kt. mačerík NTS ii 265, mac̣e° Rep1 59, Pr. mučerík, məṣkerík, muṭkurīˊk, Shum. mã̄c̣hāˊrik, Kal.rumb. mac̣hḗrik, Bshk.māˊc̣ēr, Phal. māc̣hurīˊ f.; Sh.koh. măc̣hāri f. ʻ bee ʼ, gil. (Lor.) m*l c̣hari ʻ bee, wasp, hornet ʼ (in latter meaning poss. < *makṣātara -- ); P. makhīr m. ʻ bee ʼ, kgr. ʻ honey ʼ; -- Gaw. mã̄c̣(h)oṛík with unexpl. -- ṛ -- . (CDIAL 9990) *mākṣikamadhu ʻ honey ʼ. [mākṣiká -- , mádhu -- ]

P. mākhyō̃ f., mākho m. ʻ honey, honeycomb ʼ.(CDIAL 9991) مچئِي mac̱ẖaʿī, s.f. (6th) A bee in general. Sing. and Pl. سره مچئِي saraʿh-mac̱ẖaʿī, s.f. (6th). Sing. and Pl.; or دنډاره ḏḏanḏḏāraʿh, s.f. (3rd) A hornet, a wasp. Pl. يْ ey. See ډنبره (Pashto) माक्षिक [p= 805,2] mfn. (fr. मक्षिका) coming from or belonging to a bee Ma1rkP. मक्षिकः makṣikḥ मक्षि makṣi (क्षी kṣī) का kāमक्षिकः मक्षि (क्षी) का A fly, bee; भो उपस्थितं नयनमधु संनिहिता मक्षिका च M.2.-Comp.-मलम् wax. madhu

मधु a. -मक्षः, -क्षा, -मक्षिका a bee. (Samskritam) )

माक्षिक [p= 805,2] n. a kind of honey-like mineral substance or pyrites MBh. उपधातुः An inferior metal, semi-metal. They are seven; सप्तोपधातवः स्वर्णं माक्षिकं तारमाक्षिकम् । तुत्थं कांस्यं च रातिश्च सुन्दूरं च शिलाजतु ॥ उपरसः uparasḥउपरसः 1 A secondary mineral, (red chalk, bitumen, माक्षिक, शिलाजित &c).(Samskritam) மாக்கிகம் mākkikam, n. < mākṣika. 1. Bismuth pyrites; நிமிளை. (நாமதீப. 382.) 2. Honey; தேன். (நாமதீப. 410.) செம்புத்தீக்கல் cempu-t-tīkkal

The method of cire perdue is recorded on a Chinese text:![]()

*

Addenda: mákṣā -- : S.kcch. makh f. ʻ fly ʼ; WPah.kṭg. mákkhɔ, máṅkhɔ m. ʻ fly, large fly ʼ, mákkh

1. WPah.bhad. māċhī ʻ bee ʼ, khaś. mākhī; -- Pk. makkhia -- , macchia -- n. ʻ honey ʼ; Ash. mači, mačík ʻ sweet, good ʼ, mačianá ʻ honey ʼ; Wg. mác̣i, mäc̣ ʻ honey ʼ, Kt. mac̣ī˜, Pr. maṭék, Shum. mac̣hī, Gaw. māc̣hī, Kal.rumb. Kho. mac̣hí, Bshk. mē̃c̣h, Phal. mn/ac̣hī, mḗc̣hī, Sh. măc̣hīˊ f., S. L. mākhī f., WPah.bhiḍ. māċhī n., H.mākhī f.

2. K. mã̄ch, dat. °chas m. ʻ honey ʼ, WPah.bhal. māch n. -- For form and meaning of Paš. māš, mōṣ ʻ honey ʼ see NTS ii 265, IIFL iii 3, 126.

*

Ash. mačarīk, °čerīˊk ʻ bee ʼ, Wg. mac̣arīˊk, Kt. mačerík NTS ii 265, mac̣e° Rep

P. mākhyō̃ f., mākho m. ʻ honey, honeycomb ʼ.(CDIAL 9991)

मधु a. -मक्षः, -क्षा, -मक्षिका a bee. (Samskritam) )

माक्षिक [p= 805,2] n. a kind of honey-like mineral substance or pyrites MBh. उपधातुः An inferior metal, semi-metal. They are seven; सप्तोपधातवः स्वर्णं माक्षिकं तारमाक्षिकम् । तुत्थं कांस्यं च रातिश्च सुन्दूरं च शिलाजतु ॥ उपरसः uparasḥउपरसः 1 A secondary mineral, (red chalk, bitumen, माक्षिक, शिलाजित &c).(Samskritam) மாக்கிகம் mākkikam, n. < mākṣika. 1. Bismuth pyrites; நிமிளை. (நாமதீப. 382.) 2. Honey; தேன். (நாமதீப. 410.) செம்புத்தீக்கல் cempu-t-tīkkal

"The “Leopards Weight” (Balochistan, late fourth or early third millennium B.C.) is one of the best examples of these developments: the lost-wax copper jacket, with its opened hollow shape, constitutes an extraordinary technical achievement.(Mille, B., Bourgarit, D., and Besenval, R. 2005. 'Metallurgical study of the 'Leopards weight' from Shahi-Tump (Pakistan)', in C. Jarrige and V. Lefevre, eds., South Asian Archaeology 2001, Editions Recherches sur les Civilisations, Paris: 237-44) True hollow casting does not appear until the third millennium B.C., as illustrated by the manufacture of statuettes, including the Nausharo bull figurine (Balochistan, 2300–2100 B.C.), or those from BMAC sites in Central Asia (based upon analyses of items in the Louvre collections). The birth of the lost-wax casting process can also be paralleled with the first emergence of alloying in South Asia, as many of these early lost-wax cast artefacts were made of a copper-lead alloy (c. 10–40 wt% Pb and up to 4 wt% As). Significantly, it seems that the copper-lead alloy was solely dedicated to artefacts made using the lost-wax technique, a choice no doubt driven by the advantageous casting properties of such an alloy." (Mille, Benoit, On the origin of lost-wax casting and alloying in the Indo-Iranian world, in: Lloyd Weeks, 2007, The 2007 Early Iranian metallurgy workshop at the University of Nottingham)

Novel imaging approach reveals how ancient amulet was made

November 15, 2016, CNRS

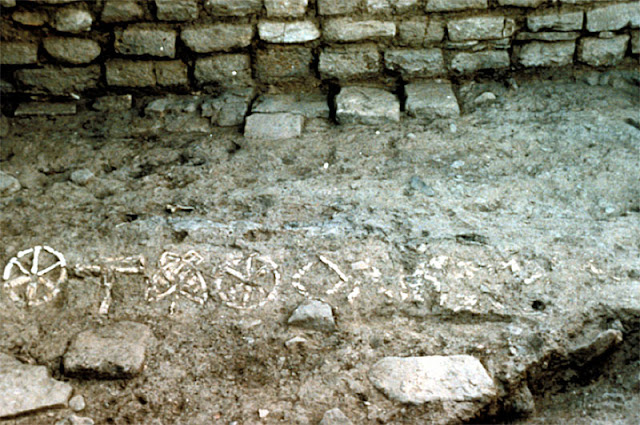

Photograph of the MR2 archaeological site at Mehrgarh occupied from 4 500 to 3 600 BC, where the amulet was found. Credit: C. Jarrige, Mission archéologique de l'Indus

At 6000 years old, this copper amulet is the earliest lost-wax cast object known. Now, researchers have finally discovered how it was made, using a novel UV-visible photoluminescence spectral imaging approach. All the parameters of elaboration process, such as the purity of the copper, and melting and solidification temperatures, are now accurately known. This work has enabled the scientists to solve the mystery of the invention of lost-wax casting, a technique that led to art foundry. Resulting from a collaboration1 between researchers from the CNRS, the French Ministry of Culture and Communication and the SOLEIL synchrotron, the work is published on 15 november 2016 in the journal Nature Communications.

The researchers examined a copper amulet, discovered in the 1980s at a site that was occupied 6,000 years ago and had been a focal point for innovation since Neolithic times: Mehrgarh, in today's Pakistan. The shape of the object shows that it was designed using the earliest known precision casting technique, lost-wax casting (still in use today). The process begins with a model formed in a low melting point material such as beeswax. The model is covered with clay, which is heated to remove the wax and then baked. The mould is filled with molten metal and then broken to release the metal object. This was all that was known about the process used to make the copper amulet until it was subjected to a novel photoluminescence approach, which revealed that it had an unexpected internal structure.

Although the amulet today consists mainly of copper oxide (cuprite), it emits a non-uniform response under UV-visible illumination. Between the dendrites formed during initial solidification of the molten metal, the researchers found rods that were undetectable using all other approaches tested. The shape and arrangement of the rods enabled the team to reconstruct the process used to make the amulet with an unprecedented level of detail for such a corroded object.

6,000 years ago, following high-temperature solidification of the copper forming it, the amulet was made up of a pure copper matrix dotted with cuprite rods, resulting from the oxidizing conditions of the melt. Over time, the copper matrix also corroded to cuprite. The contrast observed using photoluminescence results from a difference in crystal defects between the two cuprites present: there are oxygen atoms missing in the cuprite of the rods, a defect that is not present in the cuprite formed by corrosion.

This innovative imaging technique, with high resolution and a very wide field of view, made it possible to identify the ore used (extremely pure copper), the quantity of oxygen absorbed by the molten metal, and even the melting and solidification temperatures (around 1072 °C). The discovery illustrates the potential of this new analytical approach, which can be applied to the study of an extremely wide range of complex systems, such as semiconducting materials, composites and, of course, archaeological objects.

The Signboard was discovered lying on the ground,near the gateway of Dholavira.

The three-part proclamation message of the Dholavira Signboard transcribed:

There are three proclamations on the signboard with three segments of messages.

Segment 1

eraka, arā 'nave of wheel, spoke' rebus: eraka moltencast, arā 'brass'

khuṇṭa 'peg'; khũṭi = pin (Marathi.) Rebus: kuṇṭha munda (loha) 'hard iron (native metal)' (Munda)

loa 'ficus gloomerata' (Santali) Rebus: loh 'copper (metal)' PLUS karaṇika 'ears' rebus: karaṇika engraver, 'writer' (Telugu)

Thus, segment 1 reads: moltencast brass, hard metal, copper (metal) engraver;

An alternative reading of Signs 391 and 256 on Segment 1 of the signboard proclamation is possible based on the appended report on cire perdue spoked wheels made in Mehrgarh. The two signs can be read as the expression akṣaracaṇa 'scribe'; the early Meluhha rendering of the expression could be arkārācaṇa.

The suffix कूट signifies an alloy: cf. N. kã̄so ʻ bronze, pewter, white metal ʼ, kas -- kuṭ ʻ metal alloy ʼ(CDIAL 2987) L. khoṭ f. ʻ alloy, impurity ʼ, ˚ṭā ʻ alloyed ʼ, awāṇ. khoṭā ʻ forged ʼ; P. khoṭ m. ʻ base, alloy ʼ (PhonPj 117 < kauṭya -- ), f. ʻ vice, blemish ʼ, khoṭṭā ʻ vicious, impure ʼ; Ku. N. khoṭ ʻ fault ʼ; H. khoṭ m.f. ʻ deceit ʼ, ˚ṭā ʻ false, base ʼ; Marw. khoṭo ʻ bad ʼ; OG. khoṭaüṁ ʻ untrue ʼ, G. khoṭ f. ʻ mistake, loss, want ʼ, ˚ṭī f. ʻ waste of time ʼ, ˚ṭũ ʻ alloyed, bad, lazy ʼ; M. khoṭ f. ʻ falsehood, loss in trade ʼ, ˚ṭā ʻ false, alloyed ʼ, ˚ṭī ʻ delayed ʼ.(CDIAL 3931)

Segment 2

kana, kanac 'corner' (Santali); kañcu 'bronze' (Telugu) kan- 'copper work' (Tamil).

a. eraka, arā 'nave of wheel, spoke' rebus: eraka moltencast, arā 'brass'

b. kanac 'corner', mũhã̄ 'bun ingot, lozenge shape',kuṭila— 'bent' Rebus: kañcu mũhã̄ kuṭila 'bell-metal ingot, bronze'

First two signs a, b.dul eraka, arā c. dhatu

a, b: eraka, arā 'nave of wheel, spoke' rebus: eraka moltencast, arā 'brass'

Reading of a pair of 'spoked wheel hieroglyphs as hypertext': dula 'two, pair' rebus: dul 'metal casting' PLUS eraka, arā 'nave of wheel, spoke' rebus: eraka moltencast, arā 'brass'

c. ḍato 'claws or pincers (chelae) of crab Rebus: dhatu 'mineral' (Santali)

Thus, segment 3 reads together: metalcasting moltencast brass, minerals

https://tinyurl.com/yblannfg This is an addendum to: Wealth accounting classification ledgers & Arthaśāstra Economics 101 Indus Script dictionary https://tinyurl.com/yctvpzgk With the Indus Script Dictionary made available, some of the 10 'hieroglyphs/hypertexts' of the Dholavira signboard have been read rebus with variant expressions (plain texts).https://tinyurl.com/y8xt9qrk The message of the Signboard of Dholavira is a proclamation of metallurgical competence of the metalsmiths of Dholavira, who produce qualty metal castings, metalware and also engrave on copper (metal).

Dholavira Signboard inscription of gypsum inlays on wood measures 3 m. long. Each of the 10 signs is 37 cm. high and 25 to 27 cm. wide and made of pieces of white gypsum inlays; the signs were apparently inlaid in a wooden plank. The conjecture is that this wooden plank was mounted on the Northern Gateway as a Signboard. The message is intended to be a proclamation for seafaring merchants to see from across the PErsian Gulf as they approach the Dholavira citadel.

Dholavira signboard is a three-part message, each segment starts with a spoked-wheel hieroglyph.

Hence, Dholavira Signboard is read from left to right.

आर n. v.l. for अर q.v. , a spoke MBh. i , 1498 (ed. Bomb. i , 33 , 4 reads अर). ará m. ʻ spoke of a wheel ʼ RV. 2. āra -- 2 MBh. v.l. [√r̥ ]1. Pa. ara -- m., Pk. ara -- , ˚ga -- , ˚ya -- m.; S. aro m. ʻ spoke, cog ʼ; P. arm. ʻ one of the crosspieces in a cartwheel ʼ; Or. ara ʻ felloe of a wheel ʼ; Si. ara ʻ spoke ʼ.2. Or. āra ʻ spoke ʼ; Bi. ārā ʻ first pair of spokes in a cartwheel ʼ; H. ārā m. ʻ spoke ʼ, G. ārɔ m.(CDIAL 594)*nēmiyāra ʻ felly -- spoke ʼ. [*nēmiya -- , ará -- ]Bi. (Shahabad) lewārā ʻ second pair of spokes of a cartwheel ʼ, Mth. (SE Tirhut) nĕbārā; -- Bi. nimārā< *niṽ -- or poss. < *nēmyāra -- . -- H. niwār see *nēmiyākāra (CDIAL 7595) आर a corner; an angle; m. a bore

Cognate word is:"Orichalcum or aurichalcum /ˌɔːrɪˈkælkəm/ is a metal mentioned in several ancient writings, including the story of Atlantis in the Critias of Plato. Within the dialogue, Critias (460 – 403 BC) claims that orichalcum had been considered second only to gold in value and had been found and mined in many parts of Atlantis in ancient times..The name is derived fromthe Greek ὀρείχαλκος, oreikhalkos (from ὄρος, oros, mountain

and χαλκός, chalkos, copper), meaning literally "mountain copper"....The Romans transliterated "orichalcum" as "aurichalcum", which was thought to literally mean "gold copper". It is known from the writings of Cicero that the metal which they called orichalcum resembled gold in color but had a much lower value. Orichalcum has been held to be either a gold-copper alloy, a copper-tin or copper-zinc brass, or a metal or metallic alloy no longer known...Aristotle in De mirabilibus auscultationibus (62) describes a type of copper that is "very shiny and white, not because there is tin mixed with it, but because some earth is combined and molten with it." This might be a reference to orichalcum obtained during the smelting of copper with the addition of "cadmia", a kind of earth formerly found on the shores of the Black Sea, which is attributed to be zinc oxide."(Zhirov, Nicholas F. (2001). Atlantis: Atlantology: Basic Problems. The Minerva Group, Inc. p. 46. )

Copper forms alloys more freely than most metals and with a wide range of alloying elements to produce the following alloys:

Brass is the generic term for a range of copper-zinc alloys with differing combinations of properties, including strength, machinability, ductility, wear-resistance, hardness, colour, hygienic, electrical and thermal conductivity, and corrosion-resistance.

Bronze alloys are made from copper and tin, and were the first to be developed, about four thousand years ago. They were so important that they led to a period in time being named the Bronze Age.

Gunmetals are alloys of copper with tin, zinc and lead and have been used for at least 2000 years due to their ease of casting and good strength and corrosion resistance.

Copper-nickel alloys have excellent resistance to marine corrosion, high thermal conductivity and low susceptibility to attachment of marine macro-oragnisms. The addition of nickel to copper improves strength and corrosion resistance, but good ductility is retained.

Nickel-silver alloys are made from copper, nickel and zinc, and can be regarded as special brasses. They have an attractive silvery appearance rather than the typical brassy colour.

Beryllium-copper is the hardest and strongest of any copper alloy, in the fully heat treated and cold worked condition. It is similar in mechanical properties to many high strength alloy steels but, compared to steels, it has better corrosion resistance.

There are more than 400 copper alloys, each with a unique combination of properties, to suit many applications, manufacturing processes and environments.

"Brass is a metal alloy that is always made with a combination of copper and zinc. By varying the amount of copper and zinc, brass can be made harder or softer. Other metals — such as aluminum, lead, and arsenic — may be used as alloying agents to improve machinability and corrosion resistance." https://www.thebalance.com/composition-of-common-brass-alloys-2340109

To Make Brass and Alloys

·

The fusion of metals and the mode of mixing them in the crucible to form alloys require much care, because alloys are very difficult to make, especially when the metals, of which they are composed are of such a character as have a kind of antipathy for each othersuch, for instance, as copper and lead. The method to pursue in mixing them is as follows :First, melt the least fusible of the metals (that requiring the highest temperature) of which the alloy is to be composed, and after it is fused, keep up the heat until the metal acquires such a temperature as will bear the introduction of the other metals without instantaneous and sensible cooling. After this, introduce the other metals in the order of their inf usibilitythe most difficult to melt first. Whatever may be the proportions of the metals, it is indispensable to melt the most refractory first, and especially when it is to be the principal base, such as copper in all bl8sses. The liquidity of this metal gives, indeed, the measure of the temperature necessary to complete the alloy All the metals to be added, after the most refractofY is first added, should be heated in the flame of the furnace, in order to elevate their temperature, so that there should be as little difference as possible between the heat of the molten metal in the crncible, and that to be added to it. This is especially necessary when a volatile metal, like zinc, is to be added to copper, because when it is melted very suddenly, it is liable to crack the crucible. The contents of the crucible must be stirred well after the introduction and fusion of each of the component parts of the alloy. When all are added, the crucible is covered, and an increased heat given to the fireintense according to the difficulty with which the metals enter into fusion. In alloys containing a large proportion of zinc, the surface of the metal in the crucible should be covered with a thin layer of charcoal powder. This precaution is not necessary, unless the alloy contains a metal requiring a high temperature for its fusion, as, for instance, copper or iron. In alloys oontaining tin, however, a laler of charcoal placed in the crucible is liable to convert part of the metal into dross, therefore ground clean sand should be used in place of it. All alloys should be vigorously stirred when run into molds. The crucibles employed should be thoroughly cleaned after each operation. Such are the general conditions which should be followed in making alloys. Copper melts at 1920 Fah. ; zinc at 700 Fah. ; lead at 590 Fah. ; tin at 450 Fah. ; cast-iron at 2100 Fah. A dull red heat is estimated at 1489 Fah. ; a bright red heat at 1830 Fah., and a white heat at 2910 Fah. In practice it is generally found that a minute q11antity of old, introduced into a new alloy imparts to the composition greater homogenety. Alloys should be first cast into ingots, then re-melted to be cast into boxes, or any article for which they are required. Why this should be done is simply a matter of practical experience, it having been found that castings of bronze and brass give, at the second melting (when the proportions of the metal are correct), a cast of a superior grain and a greater soundness. An alloy composed of zinc, tin, lead and copper, should be made by forming the three first metals into an alloy and casting them into ingots, then melting the copper, and adding this alloy to it. By this mode of making the copper alloy, a very superior casting is obtained. In England where the manufacture of brass is carried on very extensively, the furnaces employed for smelting have movable covers of a dome shape. The crucibles employed are of Stourbridge clay, one foot deep and eight inches in diameter, each furnace holding nine crucibles. The duration of a charge is twelve hours ; the fuel used is coal and coke, and 64 pounds of copper and 88 pounds of ground calamine (zinc ore) are thc proportions of each charge. When a heat of twelve hours is completed, the crucibles are taken out with tongs, the brass is skimmed to remove the slag, and the molten alloy then run into ingot molds. Muntz metal, so well known, is composed of 60 parts copper and 40 parts of zinc. Muntz obtained a patent in England for the application of brass sheathing for ships, and when he died a few years since, he left a fortune of 600,000about three millions of dollarsall made by his patent. He was an able business man, and knew how to work his patent to the best advantage, hence his great success. A brass composed of 4.69 copper and 31 zinc is very suitable for hammering. A brass of 5.64 copper and 36 zinc is usefulfor brazing iron ; 6.75 copper and 25 zinc ; 7.5It copper, and 27t zinc. In general, common brass may be calculated to contain 2 parts of copper and 1 of zinc. Dutch metal is composed of 84.5 copper and 15.5 of zinc. It is of a pale yellow color, and so malleable as to be capable of beating out into leaves, and so thin as to be employed for cheap gilding. Chinese brass is composed of 56.9 copper, 38.27 zinc, 3.30 lead, 1.08 tin, and 1,48 iron. It is very strong and durable. A little lead improves bradS for turning purposes, and it is usual to put it in just before pouring out, and about three ounces of lead to ten pounds of brass is the amount used. Fine brass wire is woven into fabrics liKe those of cotton yarn for sieves, bolting cloths, &c. Tin wire is made into a warp for the loom, the weft wound on a spool, and placed in a shuttle which is thrown by the weavers by hand, from side to side, in the same manner that old-fashioned hand loom cloth weaving was executed. Two men are necessary to work one loom, each throwing the shuttle -alternately. Brass wire has s?me peculiar properties. When annealed it is very soft, easily bent, and woven in the loom, but it must be rendered elastic for common use. The elasticity or spring is imparted to it by stretching and heating in a frame ; in other words, "the spring is licked into it." When kept fa- a considerable length of time in a state of hikh tension, brass wire is liable to snap suddeaty. It should therefore never be employed, as it oftentimes is, for suspending chandeliers and such like objects. ------------- . ,--------- Nitre Beds.At Bahie, in the Brazils, near Sao Francisco river, 180 leagues from the city of Bahia, a great natural deposit of nitrate of soda has been discovered, extending sixty miles along the valley.

This article was originally published with the title "To make Brass and Alloys" in Scientific American 13, 48, 381 (August 1858)

doi:10.1038/scientificamerican08071858-381a