Mirror: http://tinyurl.com/nfq3bsv

Ancient artisans of the Bronze Age have bequeathed an extraordinary heritage wrought by a veritable revolution in metallurgy. Bhāratam Janam and their kindred aatman -- the artisans of Dong Son, Vietnam have also made their noteworthy contributions. The most significant contribution, in my view, is the documentation of the metalwork in Indus Script Corpora, apart from innovations in cire perdue (lost-wax) metalcasting technologies, creation of new alloys such as bronze, brass and pewter and the wondrous musical Dong Son Bronze drums as the seafaring merchants spread their wares on the Maritime Tin Route from Hanoi to Haifa. The pinnacle of achievement is signified by the iron pillars of Dhar, Mount Abu, Udayagiri (now in Delhi Qutb Minar premises), and Kodachadri. All these iron pillars are examples of dhwaja skambha-s presented by artisans to temples to venerate the divine, sacred principle, the guidepost of lives: dharma-dhamma. They are not artefacts engineered to pronounce their glorious achievements but to praise and celebrate the glory of that divine, sacred principle. Such was the dedication, l'acte gratuite of Bhāratam Janam.

In this zoom-in image, the thumb of the dancing girl and the lighted wick, 'varti' of thediya are shown, on the edges of the diya, methinks. The diya is held in her left palm, the outline of which merges with the bottom of the earthen diya, dīpam which is a primordial metaphor of Bhāratiya sabhyatā. It is just amazing that within a short space of about 1 cm. cube, the artisan is able to achieve such orthographic, sculptural precision.

Maybe, I am wrong, but I see it as an earthen lamp, a diya (deepam) with a wick which can be lighted and also 'seen', 'read' -- orthographically recognized -- to signify an Indus Script hieroglyph: 'wick' : várti

Maybe, I am wrong, but I see it as an earthen lamp, a diya (deepam) with a wick which can be lighted and also 'seen', 'read' -- orthographically recognized -- to signify an Indus Script hieroglyph: 'wick' : vártiदीप [ dīpa ] m (S) A lamp. 2 A lampstand. 3 fig. A lamp or light; of which five sorts are treated in five sections of the पंचदशीग्रंथ, named ध्यानदीप, चित्रदीप, नाटकदीप, तृप्तिदीप, कूटस्थदीप.दीपपूजा [ dīpapūjā ] f (S) The worship of lamps (upon the last day of आषाढ &c.)दीपमाळ [ dīpamāḷa ] f (दीप & माळ) A row of lamps. 2 A stone-pillar in front of a temple, to support lamps on festive occasions. 3 Applied to a tall, slender, unsightly woman.दीप्ति [ dīpti ] f S Light, lustre, splendor, refulgence. Ex. गृहीं दीप्ति त्या अद्रुता बाळकाची.दीप्तिमान् [ dīptimān ] a S Bright, glowing, luminous. dīpa m. ʻ lamp ʼ ĀśvGr̥., °paka -- m., °pikā -- f. Hariv. [√

This reading is consistent with the other hieroglyphs signified on the statue: for example, 'wristlets, bracelets', 'hair-knot' -- all related in rebus renderings in Meluhha to metalwork. Her nakedness is also relatable to metalwork, signified by kuThi 'pudendum muliebre' Rebus: kuThi 'smelter'.

The deepalakshmi tradition in bronze utsavabera created in Hindu tradition and the deepamala in Jejuri are a celebration of the Atharva Veda Skambha Sukta. So are the iron pillars.

The Vedic effulgence from yajnakunda finds its reflection -- parallel tradition, in a continuum -- in the fiery agni of smelters and furnaces of Bharatam janam, 'metalcaster folk'. भरत (p. 603) [ bharata ] n A factitious metal compounded of copper, pewter, tin &c.भरताचें भांडें (p. 603) [ bharatācē mbhāṇḍēṃ ] n A vessel made of the metal भरत. 2 See भरिताचें भांडें.भरती (p. 603) [ bharatī ] a Composed of the metal भरत.(Marathi. Molesworth).

See decipherment at

This Indus Script Corpora documentation of ca. 2500 BCE takes us to another artefact, a sword presented to Alexander on the banks of River Vitasta (Jhelum) ca. 327 BCE.

This lamp on this bronze statue of ca. 2500 BCE leads us to an event of ca. 327 BCE when Alexander received the gift of a sword from Purushottama on the banks of River Vitasta (Jhelum).

It is no ordinary sword. It is a steel sword make of ukku in southern Bhāratam. The ukku steel was called wootz and attained fame as Damascus sword as the word of the marvels of metallurgical skills of Bhāratam Janam spread far and wide into Eurasia. An event is recorded in a painting celebrating Bronze Age history; the event is the gift of an ukku sword by Purushottama to Alexander after Alexander's army had mutinied and Alexander had decided to retreat from the failed mission on the banks of Vitasta (Jhelum) river. This celebration is a high-water-mark of the revolution which preceded the event: the revolution of the Bronze Age when artisans had created new alloys and new methods of metalcasting such as cire perdue lost-wax casting to create exquisite metal implements and artefacts like the dancing girl of Mohenjo-daro carrying a lamp in her palm.

Indus Script Corpora documented by Bhāratam Janam is an extraordinary catalogus catalogorum of metalwork in an extensive area spanning the Maritime Tin Route from Hanoi to Haifa. Indus Script hieroglyphs also signify metalwork on cylinder seals of Ancient Near East, in particular from Assur to Kultepe and on cire perdue artefacts of Dong Son Bronze Drums and Nahal Mishmar scepters and standards.

शैक्य-अयसम् Damasked steel; शकदेवाय चिक्षेप सर्वशैक्यायसीं गदाम् Mb.6.54.24; शैक्यायसानि वर्माणि कांस्यानि च समन्ततः 7.119.42 (com. शैक्यायसानि शोणितायोमयानि).(Samskritam.Apte) शैक्य [p= 1089,2] damasked (?) MBh.pointed (for शैख्य) MW. pointed (for शैख्य) MW.mfn. (cf. शैक्य) pointed , spiked MW.(Monier-Williams)बट्टलोहकम् baṭṭalōhakamबट्टलोहकम् Damasked steel. bhráṣṭra n. ʻ frying pan, gridiron ʼ MaitrS. [√bhrajj ]Pk. bhaṭṭha -- m.n. ʻ gridiron ʼ; K. büṭhü f. ʻ level surface by kitchen fireplace on which vessels are put when taken off fire ʼ; S. baṭhu m. ʻ large pot in which grain is parched, large cooking fire ʼ, baṭhī f. ʻ distilling furnace ʼ; L. bhaṭṭh m. ʻ grain -- parcher's oven ʼ, bhaṭṭhī f. ʻ kiln, distillery ʼ, awāṇ. bhaṭh; P. bhaṭṭh m., °ṭhī f. ʻ furnace ʼ, bhaṭṭhā m. ʻ kiln ʼ; N. bhāṭi ʻ oven or vessel in which clothes are steamed for washing ʼ; A. bhaṭā ʻ brick -- or lime -- kiln ʼ; B. bhāṭi ʻ kiln ʼ; Or. bhāṭi ʻ brick -- kiln, distilling pot ʼ; Mth. bhaṭhī, bhaṭṭī ʻ brick -- kiln, furnace, still ʼ; Aw.lakh.bhāṭhā ʻ kiln ʼ; H. bhaṭṭhā m. ʻ kiln ʼ, bhaṭ f. ʻ kiln, oven, fireplace ʼ; M. bhaṭṭā m. ʻ pot of fire ʼ, bhaṭṭī f. ʻ forge ʼ. -- Xbhástrā -- q.v.bhrāṣṭra -- ; *bhraṣṭrapūra -- , *bhraṣṭrāgāra -- .Addenda: bhráṣṭra -- : S.kcch. bhaṭṭhī keṇī ʻ distil (spirits) ʼ.(CDIAL 9656)

ఉక్కు (p. 0149) [ ukku ] ukku. [Tel.] n. Steel. Strength, courage, pride, vigour, potency.అయస్సారము, బలము, శౌర్యము . Steadiness.స్థైర్యము. తెలగ ఉక్కు . A very tough sort of steel. R. v. 197.ఉక్కు తీగె ukku-tīge. n. Steel wire.ఉక్కుతునక

orఉక్కుముక్క ukku-tunaka. n. A bit of steel, a brave, sharp or active man.ఉక్కుసున్నము ukku-sunnamu. n. Ashes of calcined iron, scoriæ calx.ఉక్కరి ukk-ari. (ఉక్కు +అరి ) A man, a hero.శూరుడు, ధీరుడు . Ta. uruku (uruki-) to dissolve (intr.) with heat, melt, liquefy, be fused, become tender, melt (as the heart), be kind, glow with love, be emaciated; urukku (urukki-) to melt (tr.) with heat (as metals or congealed substances), dissolve, liquefy, fuse, soften (as feelings), reduce, emaciate (as the body), destroy; n. steel, anything melted, product of liquefaction; urukkam melting of heart, tenderness, compassion, love (as to a deity, friend, or child); urukkiṉam that which facilitates the fusion of metals (as borax). Ma. urukuka to melt, dissolve, be softened; urukkuka to melt (tr.); urukkam melting, anguish; urukku what is melted, fused metal, steel. Ko. uk steel.

Ka. urku, ukku id. Koḍ. ur- (uri-) to melt (intr.); urïk- (urïki-) id. (tr.);ukkï steel. Te. ukku id.Go. (Mu.) urī-, (Ko.) uṛi- to be melted, dissolved; tr. (Mu.) urih/urh- (Voc. 262).

Konḍa (BB) rūg- to melt, dissolve. Kui ūra (ūri-) to be dissolved; pl. action ūrka (ūrki-); rūga (rūgi-) to be dissolved. Kuwi (Ṭ.) rūy- to be dissolved; (S.) rūkhnai to smelt; (Isr.) uku, (S.) ukku steel.(DEDR 661)

Hieroglyph: Mora [the contracted, regular P. form of *Sk. mayūra, viâ *ma -- ūra>mora. See also Geiger, P.Gr. § 27 & Pischel, Prk. Gr. § 166. -- Vedic only mayūrī f. pea -- hen] a peacock Jii. 275 (˚upasevin, see C. on this passage);vi. 218, 497; PvA 142; DhAi. 394. A peacock's tail (sometimes used as a fan) is denoted in var. terms in cpds., as mora -- kalāpa DhAi. 387; -- piccha Vini. 186; -- piñcha Vinii. 130; -- pīñja PvA 142, 176; VvA 147; -- sikali (?) KhA 49; -- hattha Vv 3344 (=mayūra -- piñjehi kataŋ makasa -- vījaniŋ); Pviii. 117 . मोर [p= 835,3] m. a peacock (= मयूर) L. (Monier-Williams)

Rebus: Perhaps also as morakkha "a peacock's eye" at VbhA 63 (morakkhaka loha, a kind of copper, grouped with pisācaloha). It is more likely however that morakkha is distorted fr. *mauryaka, patronymic of mura, a local (tribal) designation (cp. murala), then by pop. etym. connected with mora peacock. With this cp. Sk. moraka "a kind of steel" BR. (Pali)मोरकम् mōrakamमोरकम् 1 A kind of steel.(Samskritam.Apte)

Hieroglyph: पोळ [ pōḷa ] m A bull dedicated to the gods, marked with a trident and discus, and set at large. m (पोळ ) A festive day for cattle,--the day of new moon ofश्रावण or ofभाद्रपद . Bullocks are exempted from labor; variously daubed and decorated; and paraded about in worship.

Hieroglyph: पोळ [ pōḷa ] f A wall of loose stones. n C (Orपोळें ) A honeycomb.पोळा [ pōḷā ] The cake-form portion of a honeycomb.पोळें [ pōḷēṃ ] n C A cake-form or flat honeycomb.

Rebus: पोळ [ pōḷa ] magnetite (iron ore) (Munda) पोलाद (p. 533) [ pōlāda ] n (or P) Steel. पोलादी a Of steel.پولاد polād, s.m. (6th) The finest kind of steel. Sing. and Pl. Seeفولاد Pفولاد folād or fūlād, s.m. (6th) Steel. Sing. and Pl.Pفولادي folādī or fūlādī, adj. Made of steel, steel.(Pashto) pŏlādप्वलाद् or phōlādफोलाद् । मृदुलोहविशेषः m. steel (Gr.M.; Rām. 431, 635, phōlād). pŏlödiप्वला&above;दि&below; , pōlödiफोला&above;दि&below; , or phōlödiफोला&above;दि&below; (=) । लोहविशेषमयः adj. c.g. of steel, steel (Rām. 19, 974, 167, pōo).pŏlāduwuप्वलादुवु&below; । शस्त्रविशेषमयः adj. (f. pŏlādüvüप्वलाद&above;वू&below; ), made of steel (H. v, 4).(Kashmiri)

tarḵẖaʿh aospīnaʿh, s.f. (3rd) Bar-iron (particularly the iron brought into Afg̠ẖānistān from Bombay, considered very inferior). Pl.يْ ey.خوږه اوسپینه ḵẖwaj̱ẕaʿh aospīnaʿh, The iron of Ḵẖurāsān, used in making steel and for all fine work.(Pashto) A. tikhā ʻ steel,M. tīkh ʻ pungent ʼ, tīkhẽ n. ʻ steel ʼ(CDIAL 5839) M. tikhār ʻ pungent ʼ, n. ʻ steel ʼ, tikhā̆rṇẽ ʻ to sharpen ʼ.(CDIAL 5840)एषणी 1 A goldsmith's balance. -2 A probe (of iron or steel).(Samskritam.Apte)̃কার n. a blacksmith. (Bengali)

The narrative of metalwork by Bhāratam Janam is embellished by an event enshrined in painting. The event occurred ca. 327 BCE when Purushottama presented an Indian steel ukku (wootz) sword to Alexander. The painting is in SAIL Institute, Ranchi.Moola Mookambika, Kodachadri. Iron pillar.

Sankara Peetham, Kodachadri.

Rust Free Iron Pillar on top of Kodachadri Hill at Kollur, Shimoga Dt., Karnataka, India.

from fellow-metallurgists at the Karnataka Regional Engineering College, Surathkal; and the Indira Gandhi Centre for Atomic Research (IGCAR), Kalpakkam. Results of these studies, as presented here, confirm the unanimous view of the local residents that this pillar is a product of an earlier period in indigenous iron

making, and therefore deserves a detailed and serious study by scientists and technologists devoted to India’s metallurgical heritage.Popularly referred to as the Dwaja-Sthamba (flag-staff) of the![]()

temple, the Kodachadri iron mast or pillar has long been associated in the minds of most scientists, particularly metallurgists, with the pilgrim centre of Kollur, a town located in the plains, about 120 km north of the well-known port city of Mangalore in South Canara District of Karnataka. This temple with claims to be the original

temple is associated with the killing of the dumb (mooka) demon

by the lion-riding Mother Goddess in the adjoining forests, where the demon was disturbing the penance of sages and holy men devoted to the Goddess. Today Kodachadri can be reached from Kollur by jeep on a 40 km long winding and slippery mud road with many hair-pin bends, often submerged in water during the rainy season lasting from April to November. The iron flag-staff towers above the small temple (Figure 1 a) and can be sighted a few kilometers away on the road, while approaching Kodachadri. If local lore is to be believed, this flag-staff is actually the top portion of theTri- (trident) with which the Mother Goddess nailed down the wicked demon into the bowels of the earth!

A very small piece weighing a few grams only was extracted from the projecting rough surface of the pillar with the consent and cooperation of the temple priest and was later subjected to a series of modern metallographic tests at the Materials Characterization Laboratories of the Indira Gandhi Centre for Atomic Research, Kalpakkam. To the author’s surprise, the X-ray examination could not reveal definite presence of any element or compound besides pure iron (Figure 2 c), while the microscopic study revealed only grains of iron (Figure 2 b) with very little pearlite (eutectoid of iron and Fe3C, i.e. iron carbide generally referred to as cementite). However, a few greyish and many rather large dark inclusions (Figure 2 a and b) were noticed and could be subjected to microhardness testing and electron microprobe analysis. While the small globular inclusions could be identified as iron silicate containing some calcium (Ca) and phosphorus (P), the bigger irregular-shaped ones consisted of only iron oxide (Fe2O3) with traces of other elements like silicon (Si), calcium (Ca) and phosphorus (P). The VHN microhardness numbers were around 140 for the iron grains, about 155 in the pearlite-cum-matrix areas, and around 165 in the dark inclusions. From image analysis, the volume fraction of all the inclusions was estimated as less than 2.0%. It was not possible to arrive at the exact volume fraction of the greyish pearlitic area, but assuming it to be around 1.0%, the carbon content of the pillar iron can be estimated as definitely less than 0.05%.The temple top has been recently renovated, somewhat on modern lines with brick, cement and distemper (Figure 1 a, b),

and a platform has been added ostensibly to stabilize the pillar, but with possible un-thought-of and undesirable interactions in due course between the cement of the platform and the iron of the pillar. Rising not less than 10 m above the ground level, with a rectangular cross-section of 8.5 cm ´ 5.8 cm and characterized by rough, serrated and slightly reddish surface (Figure 1 b) the pillar displays evidence on top for local melting, flow of melt and solidification, caused by lightning during the monsoon period. Allowing for a total height of 14 m, including the hidden portions in the platform and below the earth, the weight of this flag-staff can be estimated as about 500 kg.

It is obvious from these preliminary investigations that the Kodachadri iron pillar is not a product of modern iron making processes. The composition of the material of the pillar, viz. less than 0.05% carbon in what looks like almost pure iron, without the usual silicon, manganese and sulphur contents one associates with modern iron and steel, and with inclusions of only iron oxide and silicate, strongly suggests age-old indigenous methods for making the so-called Adi-vasi (tribal) iron with pure iron ore and wood charcoal. The fact that this pillar has withstood the onslaught of the sun, wind and rain in living memory,and perhaps also of marine air with the Arabian Sea only 40–50 km away, is proof of its high corrosion resistance, even though its surface is not as smooth and clear as that of the Delhi pillar. Acting as a lightning arrester during the rainy season, the top of the pillar seems to have melted frequently and perhaps rapidly solidified through removal of heat by iron from the pillar itself. A metallographic study of this part of the pillar is bound to yield some interesting results.

The data reported here, although from a very small piece of the pillar, point to the need for a more thorough and systematic scientific, technological and archaeo-historical study of this iron mast, towering alone in its majesty in a remote hilly and forest area of Karnataka.

- Hadfield, R., J. Iron Steel Inst., 1912, 85, 134–174.

- Ghosh, M. K., NML Tech. J., 1963, 5, 31–45.

- Prakash, B. and Tripathi, V., Metals Mat., 1986, 2, 568–579.

- Balasubramanian, R., Curr. Sci., 1997, 73, 1057–1067.

- Joshi, M. C. and Gupta, S. K., Kind Chandra and the Mehrauli Pillar, Kusumanjali Publication, Meerut, 1989.

- Anantharaman, T. R., The Rustless Wonder – A Study of the Delhi Iron Pillar, Vigyan Prasar, New Delhi, 1997.

ACKNOWLEDGEMENTS. I thank the authorities of the Karnataka Regional Engineering College (KREC), Surathkal, and the Indira Gandhi Centre for Atomic Research (IGCAR), Kalpakkam, for their interest, encouragement and assistance in the work reported above. Ialso thank Prof. N. Venkataraman, Dr K. L.Bhat and Dr K. R. Udupa, Department of Metallurgical and Materials Engineering, KREC, Surathkal, for accompanying and assisting me during the two visits to Kollur and Kodachadri. My thanks are due to Dr Baldev Raj, Materials Group, and Dr V. S. Raghunathan, Materials Characterization Group, IGCAR, Kalpakkam, for valuable assistance in arranging for the metallographic studies reported in this paper. It is also a pleasureto thank Dr E. S. Rajagopal and Dr A. K. Raychaudhuri, former and present Directors respectively of NPL, New Delhi for their interest, encouragement and support at all times during this study.

T. R. Anantharaman

Metals and Alloys Group,National Physical Laboratory,Dr K. S. Krishnan Road,New Delhi 110 012, Indiahttp://www.iisc.ernet.in/currsci/jun10/articles13.htm

*The Kootub [Delhi], a photo by Robert and Harriet Tytler, 1858* (BL);

also: *The Kootub [Delhi]* [*Tytlers 1858b*]

http://www.columbia.edu/itc/mealac/pritchett/00routesdata/1200_1299/qutbminar/ironpillar/ironpillar.html

Iron pillar. Qutab complex.Delhi

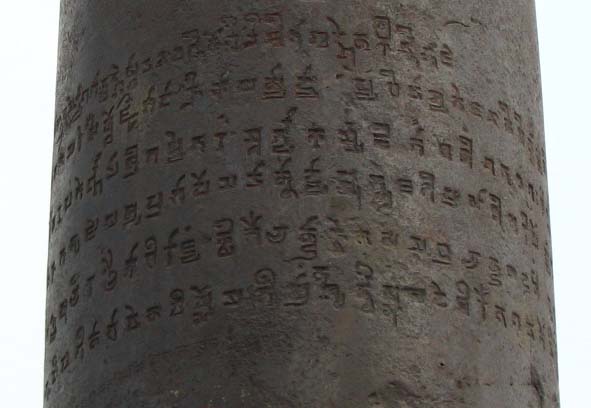

A look at the inscription on the iron pillar

Source: Courtesy of Rob McNamee, Columbia College, Jan. 2005One theory suggests the 7.2 meter tall pillar (of which 1.12 meters is underground) was probably from a temple dedicated to Vishnu (the Hindu God of life & nourishment), and intended as a standard to support a figurine of hawk-faced, winged Garuda, Vishnu’s carrier, fitted in a deep socket embedded on top of the pillar.The pillar is pinned to the ground by lead and iron projections from its buried portion.Another theory is that the pillar itself portrayed Vishnu’s mace (“gada”) surrounded by his serrated disc (“chakra”).Further evidence comes from the six-line three-stanza Sanskrit inscription in Brahmi script inscribed on the pillar. The inscription refers to its erection by Emperor Chandra, a devotee of Lord Vishnu, as a standard, or “Dhwaja Stambha”, in a temple called Vishnupada."He on whose arm fame was inscribed by the sword, when, in battle in the Vanga countries (Bengal), he kneaded (and turned) back with (his) breast the enemies who, uniting together, came against (him); He, by whom, having crossed in warfare the seven mouths of the (river) Sindhu, the Vahlikas were conquered; He, by the breezes of whose prowess the southern ocean is even still perfumed;He, the remnant of whose energy – a burning splendor which utterly destroyed his enemies – leaves not the earth even now, just like (the residual heat of) a burned-out conflagration in a great forest; He, as if wearied, has abandoned this world, and resorted in bodily form to the other world – a place won by the merit of his deeds; (but although) he has departed, he remains on earth through (the memory of his) fame;By the king, who attained sole sovereignty in the world, acquired by his very own arm and (possessed) for a long time; He who, having the name of Chandra, carried a beauty of countenance like the full moon, having in faith fixed his mind upon Vishnu, this lofty standard of the divine Vishnu was set up on the hill Vishnupada”

Palaeographically the pillar belongs to the Gupta period, but who is ‘Chandra’: Chandragupta I, Chandragupta II, who is also called Vikramaditya, or, as some believe, Samudragupta? Vishnupada is accepted as the temple caves of modern-day Udaygiri, Vidisha, Madhya Pradesh near the famous Buddhist stupas at Sanchi.

Meera Das and R Balasubhramaniam believe the pillars position in the Udaygiri caves near Sanchi, Madhya Pradesh, right on the tropic of Cancer, is where its shadow would fall at the base of a panel dedicated to Lord Vishnu at the summer solstice. ..

How metal workers could make iron that is 99.72% pure is unexplained[6]requiring temperatures higher than generated from coal. There is some rust in the underground portion of the pillar but why it remains rust free has inspired Von Daniken to claim it has extra terrestrial origins, for believers to affirm it was protected by regular annointings of ghee, or that it was made of meteorite material.

[6] According to Sir Robert Hadfield in 1912.

The primary scientific explanation combines several factors: the irons high purity with a high proportion of phosphorus and negligible sulphur and manganese, the dry, less humid climate of Delhi and less exposure to industrial pollution because it is isolated at Mehrauli, and also the enormous bulk of metal absorbs surrounding heat and releases it slowly when the temperature drops (at night) thereby ensuring it remais dry with little dew forming on the surface.

http://reflectionsofindia.com/category/india/

Mystery of Delhi's Iron Pillar unraveled

New Delhi, July 18: Experts at the Indian Institute of Technology have resolved the mystery behind the 1,600-year-old iron pillar in Delhi, which has never corroded despite the capital's harsh weather.

Metallurgists at Kanpur IIT have discovered that a thin layer of "misawite", a compound of iron, oxygen and hydrogen, has protected the cast iron pillar from rust.

The protective film took form within three years after erection of the pillar and has been growing ever so slowly since then. After 1,600 years, the film has grown just one-twentieth of a millimeter thick, according to R. Balasubramaniam of the IIT.

In a report published in the journal Current Science Balasubramanian says, the protective film was formed catalytically by the presence of high amounts of phosphorous in the iron—as much as one per cent against less than 0.05 per cent in today's iron.

The high phosphorous content is a result of the unique iron-making process practiced by ancient Indians, who reduced iron ore into steel in one step by mixing it with charcoal.

Modern blast furnaces, on the other hand, use limestone in place of charcoal yielding molten slag and pig iron that is later converted into steel. In the modern process most phosphorous is carried away by the slag.

The pillar—over seven metres high and weighing more than six tonnes—was erected by Kumara Gupta of Gupta dynasty that ruled northern India in AD 320-540.

Stating that the pillar is "a living testimony to the skill of metallurgists of ancient India", Balasubramaniam said the "kinetic scheme" that his group developed for predicting growth of the protective film may be useful for modeling long-term corrosion behaviour of containers for nuclear storage applications.

Source: Press Trust of India

| Volume 1 No.3 | November 1998 |

|

The Iron Pillar at Delhi

On the other hand, several investigators have stressed the importance of the material of construction as the primary cause for the pillar's corrosion resistance. The ideas proposed in this regard are the relatively pure composition of the iron used, presence of Phosphorus (P) and absence of Sulphur/Magnesium in the iron, its slag-enveloped metal grain structure, and passivity enhancement in the presence of slag particles.

Other theories to explain the corrosion resistance are also to be found in the literature like the mass metal effect, initial exposure to an alkaline and ammoniacal environment, residual stresses resulting from the surface finishing operation, freedom from sulphur contamination both in the metal and in the air, and surface coatings provided to the pillar after manufacture (barffing and slag coating) and during use (coating with clarified butter).

That the material of construction may be the important factor in determining the corrosion resistance of ancient Indian iron is attested by the presence of ancient massive iron objects located in areas where the relative humidity is high for significant periods in the year (for example, the iron beams in the Surya temple at Konarak in coastal Orissa and the iron pillar at Mookambika temple at Kollur situated in the Kodachadri Hills on the western coast). It is, therefore, obvious that the ancient Indians, especially from the time of the Guptas (300-500 AD), produced iron that was capable of withstanding corrosion. This is primarily due to the high P content of the iron produced during these times. The addition of P was intentional as iron produced during earlier times does not show the presence of P.

To understand the precise reason for the corrosion resistance of the Delhi iron pillar, we analysed the composition of the rust on a Gupta period corrosion resistant iron clamp and also the rust on the Delhi iron pillar. Archaeometallurgical studies form a small component of our research activities. It is clear that referring to the Delhi iron pillar as rust-less is misleading as the iron pillar derives its corrosion resistance from the passive surface film (i.e. rust) that forms on the surface. We undertook a detailed rust analysis using modern sophisticated characterization techniques like Mössbauer spectroscopy and Fourier transform infrared spectroscopy (FTIR). We summarize below some of the exciting results of our study. The present study also provides valuable insight into the corrosion resistance of steels.

Microstructure

The microstructure of the iron of the Delhi iron pillar is typical of wrought iron. Iron was produced in ancient times by solid-state reduction of iron ore using charcoal and after the reduction process, the slag particles in iron were squeezed out by hammering. This invariably resulted in the presence of slag particles and unreduced iron oxide in the microstructure. We have earlier shown by theoretical mixed potential analysis and experimental potentiodynamic polarization studies (conducted on ancient iron) that the presence of slag particles could enhance passivity in these ancient irons containing P. However, the role of P in the passivation process was not understood. The characterization of the Delhi iron pillar rust has provided clear ideas about the passive film formation process on the Delhi iron pillar.

Rust Analysis

The FTIR spectrum proved the presence of g-FeOOH, a-FeOOH and d-FeOOH. The d-FeOOH was the major component of the rust as the peak was of relatively larger height compared to the others. An interesting result from the FTIR spectrum was that there was a distinct signal from the phase FePO4.2H2O and the shoulder from this phase was also identifiable. Therefore, the results of the FTIR study indicated that the constituents of the scale were g, a and d-FeOOH, in addition to a small amount of FePO4. In order to further understand the nature of the rust, the Mössbauer spectrum obtained from the rust in the transmission mode was analysed. The presence of g-FeOOH, a-FeOOH and d-FeOOH in superparamagnetic form was confirmed. The very fine particle size of these oxyhydroxides was also confirmed. The presence of iron phosphate was also confirmed. Finally, the rust was also composed of magnetite that was incorporated with some ions.

SURFACE FILM CAHARACTERISTICS

|

|

The process of protective rust formation on the ancient Indian iron clamp can now be outlined based on the results presented above. The surface film characteristics of the Delhi iron pillar has been compared with that of mild steel in the accompanying figure. The rusting of normal mild steel and weathering steel is first addressed. When iron is exposed to the environment, the first oxides that form are the oxyhydroxides of Fe which are oxidized from Fe(II) complexes. Although several different allotropic modifications of the oxyhydroxides have been proposed to form on the surface of iron on initial exposure to the environment, there is firm evidence in the literature to suggest and prove that the first oxyhydroxide to form is g-FeOOH. After this is formed, a part of it begins to transform to another allotropic modification (a-FeOOH) and the rust at later times is composed of both these oxyhydroxides. These oxyhydroxides are not protective against corrosion and they readily crack allowing for ingress of oxygen and moisture to reach the metal surface and cause further corrosion. However, with time, a part of the FeOOH formed transforms to magnetic oxides of iron, which are much more protective than these oxyhydroxides. Mössbauer studies of rust formed on steel exposed to the environment clearly shows that Fe3O4 (more precisely to be called Fe3-xO4) forms first and this is later converted to g-Fe2O3. The formation of this magnetic oxide results in protection and the oxidation (corrosion) rates decrease once these oxides form on the surface from the oxyhydroxides. In addition to a- and g-FeOOH, there can be another oxyhydroxide d-FeOOH which can form on atmospheric exposure of iron.

It is interesting to note that d-FeOOH is generally amorphous in nature. In ordinary mild steels, this phase does not form as a continuous layer but rather in a discontinuous manner as it results due to dehydration-oxidation of the Fe(II) complexes. Therefore, the d-FeOOH that forms in ordinary mild steels is not protective in nature. However, it is possible for this d-FeOOH to form next to the metal surface as a continuous layer in which case the steel obtains corrosion resistance, as the oxyhydroxide is also amorphous in nature. The formation of d-FeOOH as a continuous layer next to the metal surface is catalysed by the presence of P (also Copper [Cu] and Chromium [Cr]) in the material. Moreover, the d-FeOOH is enriched with P and other elements that are added for improving atmospheric corrosion resistance like Cr and Cu. The presence of this amorphous layer is the reason for the excellent corrosion resistance of the so-called weathering steels.

In the case of ancient Indian iron, the atmospheric corrosion rate of the matrix material would be accelerated initially, in the presence of slag particles, leading to the enhancement of P concentration near the surface. Corrosion rate measurements (by Tafel extrapolation and weight loss methods) indicate that the short term corrosion rate of ancient Indian iron is an order of magnitude higher than that of 0.05%C mild steel in acidic environment while it is comparable in mildly alkaline environment. It must be noted that these measurements were obtained for complete immersion conditions, quite different from atmospheric exposure. Nevertheless, the initial corrosion of the matrix must lead to enrichment of P content near the surface. This is verified by compositional analysis of the metal next to the oxide which indicated enrichment of P in these regions. With the enhancement in the P concentration, the formation of d-FeOOH is catalysed and it should form as an amorphous compact layer next to the metal surface. Therefore, it appears that the presence of a significant amount of P is crucial to the corrosion resistance of the ancient Indian iron.

The process of passive film formation on the ancient Indian iron can be visualized as follows. Initially, the corrosion of the metal leads to the formation of a- and g-FeOOH. However, the presence of slag particles accelerates the corrosion of iron thereby enhancing the P concentration on the surface. This enhancement of P on the surface catalyses the formation of amorphous d-FeOOH as a compact layer next to the surface and this results in atmospheric corrosion resistance of the Delhi iron pillar. With time, conversion of this d-FeOOH to a stable form of iron oxide, i.e., magnetite, is possible. The magnetite could be doped with ions. This would further enhance the corrosion resistance of the surface film on the surface. The FTIR and Mössbauer spectra indicate the presence of iron phosphates. The presence of these phosphates would provide further corrosion resistance to the passive film by lowering ionic diffusion in the oxide and also by blocking the pores in the oxide. The golden hue of the pillar when viewed in certain orientations is due to the presence of iron phosphates. We hope to compositionally map the rust on the entire exposed surface of the pillar in the near future.

For more information contact:

Dr. R. Balasubramaniam

Department of Materials and Metallurgical Engineering

IIT Kanpur, Kanpur 208016

Telephone: (0512) 59 7089

e-mail: bala@iitk.ac.in

http://www.iitk.ac.in/infocell/Archive/dirnov1/iron_pillar.html

Review: Delhi Iron Pillar: New Insights. Balasubramaniam, R. 2002. Delhi: Aryan Books International. Pp.168, figures 33. Price Rs.1800/- ($40/-).

by D.P. Agrawal

Delhi's iron pillar (DIP) in the Qutub area has attracted the attention of archaeologists, laymen and metallurgists alike for its rust less property. Various theories have been propounded about its rust free iron. Only recently Balasubramaniam has carried out more rigorous analyses using latest techniques, as a professor of metallurgy in Indian Institute of Technology, Kanpur, these facilities were available to him.Balasubramaniam attributes these anticorrosion properties to significant presence of Phosphorus (P) in the DIP. We will presently see the technical details of his analysis. He also shows that the maximum corrosion on the DIP occurs near the joint, mainly because of presence of lead.

The book is divided into seven chapters, with one appendix on the technical details on the presence of phosphorus in ancient Indian irons. The first chapter introduces the DIP and its composition. The second chapter deals with the history of DIP which is quite authentic. Balasubramaniam gives even the transcripts of the inscriptions, a discussion of the history and association of DIP with Chandragupta II Vikramaditya, which are quite convincing. Balasubramaniam also discusses details of the palaeography of the inscriptions. He agrees with the date of 410 AD given by the famous epigraphist Hoernele. He also shows that the original location of DIP was actually in Madhya Pradesh, in the Udayagiri hills which have been identified with Vishnupadgiri. As Chandragupta II was a great devotee of Vishnu, the pillar was erected in the honour of his favourite God.

In Chapter 3, Balasubramaniam gives the structural details of the DIP; he also shows that the capital was joined with the pillar by using lead as the joining metal. He also gives a brief history of lead metallurgy in ancient India.

Chapter 4 discusses the decorative bell capital on the pillar. He also discusses the technology of shrink fitting methodology as to how the bell capital was fitted to the iron pillar. The author has illustrated the reconstruction of techniques.

In Chapter 5, Balasubramaniam has reconstructed the manufacturing techniques of the pillar, which was done through forge welding, and use of inserts. In chapter 6, the author discusses the technical details of corrosion resistance of DIP. He has illustrated the discussion with a number of x-ray diffraction and FTIR spectra and diagrams. The author also did Mossbauer spectroscopy of the rust samples. He shows that the phosphate was crystalline iron hydrogen phosphate hydride. The author also pleads for more detailed scientific studies on various aspects.

In Chapter 7, the author gives the summary of his analysis of DIP. In this chapter he also discusses the Dhar iron pillar and the other iron pillars at Chadira hills, Mandu hills, Mount Abu and also some Mughal canons. In the appendix the author has given the technical details and thermodynamic models of the origin of high phosphorous contents in ancient iron pillars. He has also compared here the ancient and modern slag. In the appendix he has shown that ancient Indian iron always produced higher phosphorous than modern iron at all temperatures. He attributes the higher P content in ancient iron to lack of use of lime (CaO) in the flux.

Balasubramaniam summarises his observations as follows:

Several new insights on the Delhi iron pillar have been presented in the present monograph. The subject of iron extraction that was practiced in ancient India was briefly discussed and specific attention was focused on the composition and microstructure of iron of the Delhi pillar. The origin of high P content in the Delhi iron pillar, in particular, and in ancient Indian iron, in general, has also been addressed.The bibliography is quite up-to-date and exhaustive, as also the index. I am sure, archaeologists, archaeometallurgists and the layman alike would welcome this book by a competent metallurgist. The profuse illustrations, both in black and colour, detailed line drawings, graphs and tables make it a very convincing case for explaining the anticorrosion properties of phosphorous, the higher content of which is due to the lack of the use of lime in the flux.

The identity of king Chandra of the Delhi iron pillar Sanskrit inscription has been critically addressed. The name Chandra firmly establishes that the king was Chandragupta II Vikramaditya. Numismatic evidence for the short name of Chandragupta II Vikramaditya being Chandra has been provided for the first time by comparing the archer gold coin types of all the Gupta monarchs. Arguments have been provided to show that the inscription was not posthumous in nature. The conquests of Chandra corroborate the conquests of Chandragupta II Vikramaditya. Numismatic and archaeological find spots have been analyzed to provide support to Chandragupta's conquests. The personal religion of Chandragupta II also lends strong support to his identification as Chandra. The identification of Chandra with Chandragupta II Vikramaditya poses the least contradictions. The locations of Vahlika and Vishnupadagiri have been critically analyzed. It is proposed, based on archaeological and historical evidence, that Udayagiri could be favorably considered as ancient Vishnupadagiri, where the iron pillar was originally erected. Careful archaeological excavations are necessary at Udayagiri to firmly confirm the original location of the iron pillar.

The various aspects related to the structural features of the pillar have been addressed. A detailed analysis of the dimensions of the pillar and its decorative bell capital has been presented. The presence of lead in various regions of the pillar has been addressed, along which the construction of the pillar has been explored in detail starting from the pillar bottom. The presence of lead in several regions of the pillar has been described and the possible implication for lead presence on the corrosion of the pillar has also been discussed. A brief discussion on the status of lead metallurgy in ancient India has been provided.

The various components that comprise the decorative bell capital have been addressed in detail and the joining methodology of the capital parts as well as the capital to the main body of the pillar has been established. Insights on the possible image of garuda, which was originally placed on the top of the capital, have been provided. The decorative capital of the Delhi iron pillar has been fabricated from individual pieces (that were produced by forge welding and not casting). The individual pieces that constitute the iron pillar's capital have been intelligently shrunk fit on a hollow cylinder in an artistic and aesthetic manner keeping sound engineering principles in mind. It is important to perform careful ultrasound measurements on all the various sections of the decorative capital in order to obtain further insights into the shrink fitting methodology.

The manufacturing methodology employed to construct the main body of the Delhi iron pillar has been elucidated. The vertical and horizontal methods of forging for manufacturing the main body of the pillar have been critically compared. Several aspects of the manufacturing methodology (hammering method, heating method, use of inserts, use of dies, possible handling method and surface finishing operation) have been discussed. Visual evidences suggest sideways addition of metal lumps with the aid of hand-held hammers with the pillar in the horizontal position. The addition of iron lumps on to the side of the pillar, with the pillar placed in the horizontal direction, appears the likely method of the manufacture of the pillar. The nature of the iron lumps that were forge welded on to the body has been discussed. The use of hand held hammers for the forging operation is also established. The ingenious method employed to handle such a large object has also been illustrated. The to-and-fro motion of the pillar during the forging operation must have been possible with the use of handling clamps on the pillar. The rotational motion of the pillar (and also handling) must have been aided by the use of rotating pegs inserted in the bottom and top cross sections of the pillar, and also on the sides of the pillar. The final surface finishing operations (hot hammering, chiselling and burnishing) produced the smooth surface and taper of the cylindrical pillar.

The current theories (environmental and material) for the corrosion resistance of the pillar have been critically reviewed. The apparent anomaly of a two-phase (iron and entrapped slag inclusions) heterogeneous structure of wrought iron of the Delhi pillar possessing superior corrosion resistance has been understood by mixed potential theory analysis. The nature of the protective passive layer on the corrosion resistant Delhi iron pillar has been addressed based on a detailed characterization of its rust. The rust is composed of iron hydrogen phosphate hydrate (FePO 4.H3PO 4.4H2O) in the crystalline form in addition to a-, y-, o-FeOOH and magnetite, all in amorphous form. The process of protective rust formation on DIP iron has been outlined based on the rust analysis. The passive film formation on the Delhi iron pillar has been contrasted with rusting of normal and weathering steels. The critical factor aiding the superior corrosion resistance of the Delhi iron pillar is the formation of crystalline iron hydrogen phosphate hydrate, as a thin layer next the metal-scale interface, which drastically lowers the rate of corrosion due to its low porosity content. The formation of protective crystalline phosphate is aided by alternate wetting and drying cycles, which is the important contribution of the atmosphere to the pillar's corrosion resistance. Therefore, the corrosion resistance of the Delhi iron pillar is due to both Delhi (the environment providing alternate wetting and drying conditions) and iron (with its high P content conferring protection by the formation of the crystalline iron hydrogen phosphate).

Suggestions have been provided at the end of each of the previous chapters on the studies that need to be conducted on the Delhi iron pillar. Scientists from the Indira Gandhi Centre for Atomic Research have conducted several scientific studies (in-situ metallography, radiography, sonography and surface potential measurements) on the Delhi iron pillar in 2001 (IGCAR 2001) and these studies should shed valuable insights. Most importantly, there is an urgent need to replace the lead sheet covering the surface of the pillar in the buried underground regions. When the pillar was re-erected by Beglar in the 19th century AD, the stone platform was constructed and a coating of lead was provided on the buried underground surface of the pillar. This uneven coating of lead (of about 3 mm in thickness) was found to be in an excellent state of preservation when the buried regions of the pillar was again excavated in 1961 on the eve of the centenary of the Archaeological Survey of India. However, the buried portion was found covered with rust layers ranging from a few mm to 15 mm. After removal of the rust scales (Pl. 36a), numerous cavities and corrosion pits were observed on the surface. The preliminary treatment of the pillar comprised of elimination of rust, earthy accretions and water- soluble salts resulting in the structure shown in Pl. 36b. The holes, cracks and cavities were consolidated and provided a rust preventive treatmen. The lead sheet coating was again provided to the surface for protecting the pillar from direct contact with mortar and the saline soil on the recommendation of the structural conservators and archaeological engineers. This new lead coating was provided much against the wishes of the Chief Chemist of ASI (Lal 1996). Therefore, the present corrosion rate of iron in the buried regions is much more than that of the exposed surface due to galvanic action with the lead layer, as lead is cathodic with respect to iron (Balasubramaniam 1999b). The iron in the buried underground region is currently subjected to intense galvanic corrosion. It has been suggested, first by Lal (1996), and recently by Anantharaman (1996) and Balasubramaniam (1997b), that the lead coating be removed and replaced with a zinc coating, because, unlike lead, zinc is anodic with respect to iron and therefore would sacrificially protect the iron underneath. However, this may not be appropriate because zinc corrodes rapidly in saline soils and the soil around the pillar, in its current location, is loaded with chlorides and sulphates (LaI1996). It is important to replace this lead coating (Pl. 38) with another suitable coating (epoxy-based coating, especially if the soil is saline, and maybe combined with cathodic protection) for proper preservation of this important cultural and scientific object (Pl. 39). The replacement of lead coating with a suitable coating must be addressed at the earliest by excavating the bottom regions of the pillar.

Although the Delhi iron pillar has been the focus of attention in the present monograph, it must be realized that there are several other large ancient iron objects in India. Some of these objects would be briefly reviewed here. The study of these objects has not been taken up on a large scale, with the reason probably being the lack of knowledge of these objects. It is anticipated that serious studies in the future will address these objects.

An interesting book on all counts.

http://www.infinityfoundation.com/mandala/t_rv/t_rv_agraw_delhi.htm

http://tinyurl.com/p2bubsu Review of book (2008): R. Balasubramanian, Marvels of indian iron through the ages IJHS pp.652-658

http://www.insa.nic.in/writereaddata/UpLoadedFiles/IJHS/Vol43_4_8_BookReviewBPrakash.pdf

https://www.scribd.com/doc/282930234/Review-of-Balasubramaniam-s-Marvels-of-Indian-Iron-Through-the-Ages-Prakash

Iron beams at the Konark Sun Temple premises.

Iron pillars, Dhar.

Image number: S0002164

Image number: S0002164The Lat Masjid (The Iron Pillar) - Dhar - Madhya Pradesh - Central India

Artist / photographer: Vernon & Co.Date: 1912

Country: India http://images.rgs.org/imageDetails.aspx?barcode=5620

S. Kalyanaraman

Sarasvati Research Center

September 28, 2015

Moola Mookambika, Kodachadri. Iron pillar.

Moola Mookambika, Kodachadri. Iron pillar.

temple, the Kodachadri iron mast or pillar has long been associated in the minds of most scientists, particularly metallurgists, with the pilgrim centre of Kollur, a town located in the plains, about 120 km north of the well-known port city of Mangalore in South Canara District of Karnataka. This temple with claims to be the original

temple, the Kodachadri iron mast or pillar has long been associated in the minds of most scientists, particularly metallurgists, with the pilgrim centre of Kollur, a town located in the plains, about 120 km north of the well-known port city of Mangalore in South Canara District of Karnataka. This temple with claims to be the original temple is associated with the killing of the dumb (mooka) demon

temple is associated with the killing of the dumb (mooka) demon  by the lion-riding Mother Goddess in the adjoining forests, where the demon was disturbing the penance of sages and holy men devoted to the Goddess. Today Kodachadri can be reached from Kollur by jeep on a 40 km long winding and slippery mud road with many hair-pin bends, often submerged in water during the rainy season lasting from April to November. The iron flag-staff towers above the small temple (Figure 1 a) and can be sighted a few kilometers away on the road, while approaching Kodachadri. If local lore is to be believed, this flag-staff is actually the top portion of theTri- (trident) with which the Mother Goddess nailed down the wicked demon into the bowels of the earth!

by the lion-riding Mother Goddess in the adjoining forests, where the demon was disturbing the penance of sages and holy men devoted to the Goddess. Today Kodachadri can be reached from Kollur by jeep on a 40 km long winding and slippery mud road with many hair-pin bends, often submerged in water during the rainy season lasting from April to November. The iron flag-staff towers above the small temple (Figure 1 a) and can be sighted a few kilometers away on the road, while approaching Kodachadri. If local lore is to be believed, this flag-staff is actually the top portion of theTri- (trident) with which the Mother Goddess nailed down the wicked demon into the bowels of the earth! The temple top has been recently renovated, somewhat on modern lines with brick, cement and distemper (Figure 1 a, b),

The temple top has been recently renovated, somewhat on modern lines with brick, cement and distemper (Figure 1 a, b),

and perhaps also of marine air with the Arabian Sea only 40–50 km away, is proof of its high corrosion resistance, even though its surface is not as smooth and clear as that of the Delhi pillar. Acting as a lightning arrester during the rainy season, the top of the pillar seems to have melted frequently and perhaps rapidly solidified through removal of heat by iron from the pillar itself. A metallographic study of this part of the pillar is bound to yield some interesting results.

and perhaps also of marine air with the Arabian Sea only 40–50 km away, is proof of its high corrosion resistance, even though its surface is not as smooth and clear as that of the Delhi pillar. Acting as a lightning arrester during the rainy season, the top of the pillar seems to have melted frequently and perhaps rapidly solidified through removal of heat by iron from the pillar itself. A metallographic study of this part of the pillar is bound to yield some interesting results.