Map of major routes and sites of Meluhha (mleccha) interaction areas, location of Tell Abraq (adapted from Potts DT. 1994 fig.5 http://tinyurl.com/yljaqdu)

In the course of my studies on hieroglyphs of ancient Near East 3rd and 2nd millennium BCE, and the Tin Road of the Bronze Age, I have come across the use of a flower used for perfume oil:tabernae montana as a hieroglyph. I find that this hieroglyph is deployed on hair combs and also on a metal, shaft-hole axe.

In interaction areas, tabernae montana glyph appears: 1. on an ivory comb discovered at Oman Peninsula site of Tell Abraq, 2. on a Bactria-Margiana Archaeological Complex stone flask and, 3. on a copper alloy shaft-hole axe-head of (unverified provenance) attributed to Southeastern Iran, ca. late 3rd or early 2nd millennium BCE 6.5 in. long, 1980.307 Metropolitan Museum of Art, New York.

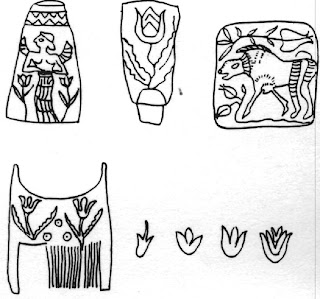

The ivory comb found at Tell Abraq measures 11 X 8.2 X .4 cm. Both sides of the comb bear identical, incised decoration in the form of two long-stemmed flowers with crenate or dentate leaves, flanking three dotted circles arranged in a triangular pattern. The occurrence of wild tulip glyph on the ivory comb can be explained.

The spoken word tagaraka connoted a hair fragrance from the flower tagaraka These flowers are identified as tulips, perhaps Mountain tulip or Boeotian tulip (both of which grow in Afghanistan) which have an undulate leaf. There is a possibility that the comb is an import from Bactria, perhaps transmitted through Meluhha to the Oman Peninsula site of Tell Abraq.

At Mundigak, in Afghanistan, only one out of a total of five shaft-hole axes analysed contained as much as 5% Sn. Such shaft-hole implements have also been found at Shah Tepe, Tureng Tepe, and Tepe Hissar in level IIIc (2000-1500 BCE).

Tell Abraq axe with epigraph (‘tulip’ glyph + a person raising his arm above his shoulder and wielding a tool + dotted circles on body) [After Fig. 7 Holly Pittman, 1984, Art of the Bronze Age: Southeastern Iran, Western Central Asia, and the Indus Valley, New York, The Metropolitan Museum of Art, pp. 29-30]. ![]()

tabar = a broad axe (Punjabi). Rebus: tam(b)ra ‘copper’ tagara ‘tabernae montana’, ‘tulip’. Rebus: tagara ‘tin’. Glyph: eṛaka ‘upraised arm’ (Tamil); rebus: eraka = copper (Kannada)

A rebus reading of the hieroglyph is: tagaraka, tabernae montana. Rebus: tagara ‘tin’ (Kannada); tamara id. (Skt.) Allograph: ṭagara ‘ram’. Since tagaraka is used as an aromatic unguent for the hair, fragrance, the glyph gets depicted on a stone flask, an ivory comb and axe of Tell Abraq.

The glyph is tabernae montana, ‘mountain tulip’. A soft-stone flask, 6 cm. tall, from Bactria (northern Afghanistan) showing a winged female deity (?) flanked by two flowers similar to those shown on the comb from Tell Abraq.(After Pottier, M.H., 1984, Materiel funeraire e la Bactriane meridionale de l'Age du Bronze, Paris, Editions Recherche sur les Civilisations: plate 20.150) Two flowers are similar to those shown on the comb from Tell Abraq. Ivory comb with Mountain Tulip motif and dotted circles. TA 1649 Tell Abraq. [D.T. Potts, South and Central Asian elements at Tell Abraq (Emirate of Umm al-Qaiwain, United Arab Emirates), c. 2200 BC—AD 400, in Asko Parpola and Petteri Koskikallio, South Asian Archaeology 1993: , pp. 615-666] Tell Abraq comb and axe with epigraph After Fig. 7 Holly Pittman, 1984, Art of the Bronze Age: Southeastern Iran, Western Central Asia, and the Indus Valley, New York, The Metropolitan Museum of Art, pp. 29-30].

"A fine copper axe-adze from Harappa, and similar bronze examples from Chanhu-daro and, in Baluchistan, at Shahi-tump, are rare imports of the superior shaft-hole implements developed initially in Mesopotamia before 3000 BC. In northern Iran examples have been found at Shah Tepe, Tureng Tepe, and Tepe Hissar in level IIIc (2000-1500 BC)...Tin was more commonly used in eastern Iran, an area only now emerging from obscurity through the excavation of key sites such as Tepe Yahya and Shahdad. In level IVb (ca. 3000 BCE)at Tepe yahya was found a dagger of 3% tin bronze. (Lamberg-Karlovsky, C.C. and M., 1971, An early city in Iran, Scientific American, 1971, 224, No. 6, 102-11; Muhly, 1973, Appendix 11, 347); perhaps the result of using a tin-rich copper ore." (Penhallurick, R.D., 1986, Tin in Antiquity, London, Institute of Metals, pp. 18-32)

Diffusion of Metallurgy: Meluhha and western Afghanistan sources of tin

"...In the later 4th and early 3rd millennia, greater tin values occur--5.3% in a pin from Susa B; and 5% in an axe from Mundigak III in Afghanistan; but these are still exceptional in a period characterized by the use of arsenical copper ...arond 270 BC, during Early Dynastic III in Mesopotamia...eight metal artifacts of forty-eight in the celebrated 'vase a la cachette' of Susa D are bronzes; four of them -- three vases and one axe -- have over 7% tin. The analyses of objects from the Royal Cemetery at UR present an even clearer picture: of twenty-four artifacts in the Iraq Museum subjected to analysis, eight containing significant quantities of tin and five with over 8% tin can be considered true bronzes in the traditional sense.a contemporary shaft-hole axe from Kish contains 4% tin, and significant amounts were detected in a few artifacts from Tepe Giyan and Tepe Yahya IVB in Iran, and Hili in Oman. Thus, we see an increasing pattern of tin usage......Gudea of Lagash (2150-2111BCE)speaks of the tin of Meluhha...the geographer Strabo (XV.2.10) who, in referring to the inhabitants of Drangiana (modern Sistan), says that they have 'only scanty supplies of wine, but they have tin in their country'...this passage..does accord well with the discoveris in the area of Herat...There are two possible routes from Afghanistan to Mesopotamia. One crosses the northern part of the Iranian plateau, along the Elburz mountains, then through the passes in the Zagros descends to Babylonia and Assyria. In the 1st millennium it was one of the principal supply routes of eastern goods to Assyria. In the 2nd millennium the tin that Assur exported to Anatolia might have followed this route. Along it are found such sites as Tepe Sialk (where the use of tin is attested in the 4th millennium), Tepe Giyan and Tepe Hissar, wehre other finds (such as lapis lazuli at Hissar) implicate them in long-distance commerce in the 3rd millennium...Recently Oman has yielded the first signs of the use of tin in the region. The analysis of a sword from Hili, dated to the mid-3rd millennium, shows a tin content of 6.5%, and a mold of a tap hole (?) associated with the remains of a furnace held metal with a tin content of 5%...At Umm an-Nar artifacts with tin contents on the order of 2% were recovered; the tin must have been mixed with the local copper...Meluhha...the use of tin is attested already in the late 4th or early 3rd millennium at Mundigak III in southern Afghanistan. Tin appears only in small quantities in artifacts from Sahr-i-Sokhta in eastern Iran and at Tepe Yahya in southern Iran...In the Indus Valley, the copper-tin alloy is known at Mohenjodaro...The discoveries of tin in artifacts at Hili, though singular, are important because the site lies in an area clearly involved in long-distance trade. However, there is no clear evidence that the site was a way-station on the route which brought tin from Afghanistan to Mesopotamia. Therefore the presence of tin at Hili indicates only that it was transported in the Gulf area, where it was also used to fill local needs. The collective indications are that western Afghanistan ws the zone able to provide the tin used in Southwest Asia in the 4th and 3rd millennia...In order to elucidate the questions raised by our findings, a project aimed specifically at tin-- its sources and metallurgy-- should be organized." (Serge Cleuziou and Thierry Berthoud, Early Tin in the Near East, in: Expedition, Vol. 25, No. 1, 1982, pp. 14-19). cf. R.J.Forbes, 1954, Extracting, smelting and alloying, in: Charles Singer, E.J.Holmyard and AR Hall (eds.), 1954, A History of Technology, Oxford, Clarendon Press. Knox, Robert, 1994, A new Indus Valley Cylinder Seal, pp. 375-378 in: South Asian Archaeology 1993, Vol. I, Helsinki. Ibid., p. 377; cf. Lamberg- Karlovsky and Tosi 1973: pl. 137.

It is likely that the sources of tin can also extend the Tin Road of Meluhha into the river beds of Sindhu and Sarasvati rivers and associated tributary rivers and water channels for panned tin obtained by prospectors.

An unresolved problem in the study of Bronze Age civilizations has been the identification of sources of tin. Arsenical bronzes of the millennia earlier to the 5th millennium were replaced by tin-bronzes creating a veritable revolution in the march of civilization.

John Muhly has highlighted and contributed significantly to the resolution of this problem. Many cuneiform texts do point to Meluhha as the major source of tin, reaching through the transit points of Magan and Dilmun along the Persian Gulf region and west of Mehergarh.

A possible scenario is presented by a geologist, TM Babu (2003) in: Advent of the bronze age in the Indian subcontinent In Mining and metal production: through the ages, eds. P. Craddock and J. Lang, London, British Museum Press, pp175-180. In this article, Babu starts with the traditions in ancient India of making idols for worship using pancha-loha (lit. five metals), creating an alloy of copper, tin, lead, zinc, arsenic and less commonly, silver and gold. A word in Tamil denoting this alloy is kol which also means ‘working in iron’. This lexeme is denoted by the hieroglyphs: tiger (kola), woman (kola), rice-plant (kolom). Similar rebus readings of hundreds of hieroglyphs on Indus writing point to the Indian sprachbund, a linguistic union which explains the presence, for example, Munda words in ancient Sanskrit texts.

John Muhly has highlighted and contributed significantly to the resolution of this problem. Many cuneiform texts do point to Meluhha as the major source of tin, reaching through the transit points of Magan and Dilmun along the Persian Gulf region and west of Mehergarh.

A possible scenario is presented by a geologist, TM Babu (2003) in: Advent of the bronze age in the Indian subcontinent In Mining and metal production: through the ages, eds. P. Craddock and J. Lang, London, British Museum Press, pp175-180. In this article, Babu starts with the traditions in ancient India of making idols for worship using pancha-loha (lit. five metals), creating an alloy of copper, tin, lead, zinc, arsenic and less commonly, silver and gold. A word in Tamil denoting this alloy is kol which also means ‘working in iron’. This lexeme is denoted by the hieroglyphs: tiger (kola), woman (kola), rice-plant (kolom). Similar rebus readings of hundreds of hieroglyphs on Indus writing point to the Indian sprachbund, a linguistic union which explains the presence, for example, Munda words in ancient Sanskrit texts.

Documenting the Tin processing tradition in India

As the pictorial gallery demonstrates, the entire tin processing industry is a family-based or extended-family-based industry. The historical traditions point to the formation of artisan guilds to exchange surplus cassiterite in trade transactions of the type evidenced by the seals and tablets, tokens and bullae found in the civilization-interaction area of the Bronze Age.

Papagudem boy wearing a bangle of tin

“Bronze articles such as ornamental mirrors, arrowheads, pins, bangles and chisels, of both low tin and high tin content, have been recovered from Lothal, the Harappn port on the Gujarat coast, which has been dated earlier than 2200 BCE. The tin content in these articles range from 2.27% to 11.82%; however, some of the articles contain no tin. Tin is said to have been brought as tablets from Babylon and mixed with copper to make an alloy of more pleasing colour and luster, a bright golden yellow. The utilization of bronze is essential only for certain articles and tools, requiring sharp cutting edges, such as axes, arrowheads or chisels. The selection of bronze for these items indicates the presence of tin was intentional…Recent discoveries of tin occurrences in India are shown in…Fig. 11.2. However, none of these occurrences shows evidences of ancient mining activity. This is because, unlike copper ores, the mining and metallurgy of the tin ore cassiterite is simple, and leaves little permanent trace…tin ore is usually recovered by simple panning of surface deposits, often contained in gravel, which soon collapse, leaving little evidence of having once been worked. Cassiterite is highly resistant to weathering, and with its high specific gravity, it can be easily separated from the waste minerals. The simple mining and metallurgical methods followed even now by Bastar and Koraput tribals in Chattisgarh and Orissa, central India, could be an indication of the methods used in the past. These tribal people produce considerable quantities of tin without any external help, electric power or chemical agents, enough to make a modern metallurgist, used to high technology, wonder almost in disbelief. Clearly though, the technology practiced has a considerable importance for those studying early smelting practices. The history of this process is poorly known. Back in the 1880s Ball (1881) related the story of a Bastar tribal from the village of Papagudem, who was observed to be wearing a bangle of tin. When questioned as to where the metal had come from, he replied that black sands, resembling gunpowder were dug in his village and smelted there. Thus it is very likely that the present industry is indigenous, and may have a long history. That being said, neither the industry or its products appear in any historical document of any period, and thus is unlikey to have been a significant supplier of metal…The tin content of cassiterite ranges from 74.94% (mean 64.2%), showing that pebbles contain about 70% to 90% of the tin oxide, cassiterite…The ore is localized in gravel beds of the black pebbles of cassiterite which outcrop in stream beds etc. and there are other indicators, in the vegetation. The leaves of the Sarai tree (Shoria robusta) growing on tin-rich ground are often covered in yellow spots, as if suffering from a disease. (The leaves were found to contain 700 ppm of tin on analysis!) Wherever the tribals find concentrations of ore in the top soil, the ground all around the area is dug up and transported to nearby streams, rivers or ponts…The loose gravelly soil containing the tin ore is dug with pick and shovel, and carried to the washing sites in large, shoulder-strung bamboo baskets. The panning or washing of the ore is carrie out using round shallow pans of bamboo. The soil is washed out, leaving the dense casiterite ore at the bottom of the pan…The ore is smelted in small clay shaft furnaces, heating and reducing the ore using charcoal as the fuel…The shft furnaces are square at the base and of brick surmounted by a clay cylindrical shaft…The charcoal acts as both the heating and reducing agent, reducing the black cassiterite mineral into bright, white tin metal…a crude refining is carried out by remelting the metal in an iron pan at about 250 degrees C. The molten tin is then poured into the stone-carved moulds to make square- or rectangular-shaped tin ingots for easy transportation. (Babu, TM, 2003, Advent of the bronze age in the Indian subcontinent in: Craddock, PT and J. Lang, Mining and Metl production through the ages, British Museum, pp.174-180). See: http://bharatkalyan97.blogspot.in/2013/06/asur-metallurgists.html

“Bronze articles such as ornamental mirrors, arrowheads, pins, bangles and chisels, of both low tin and high tin content, have been recovered from Lothal, the Harappn port on the Gujarat coast, which has been dated earlier than 2200 BCE. The tin content in these articles range from 2.27% to 11.82%; however, some of the articles contain no tin. Tin is said to have been brought as tablets from Babylon and mixed with copper to make an alloy of more pleasing colour and luster, a bright golden yellow. The utilization of bronze is essential only for certain articles and tools, requiring sharp cutting edges, such as axes, arrowheads or chisels. The selection of bronze for these items indicates the presence of tin was intentional…Recent discoveries of tin occurrences in India are shown in…Fig. 11.2. However, none of these occurrences shows evidences of ancient mining activity. This is because, unlike copper ores, the mining and metallurgy of the tin ore cassiterite is simple, and leaves little permanent trace…tin ore is usually recovered by simple panning of surface deposits, often contained in gravel, which soon collapse, leaving little evidence of having once been worked. Cassiterite is highly resistant to weathering, and with its high specific gravity, it can be easily separated from the waste minerals. The simple mining and metallurgical methods followed even now by Bastar and Koraput tribals in Chattisgarh and Orissa, central India, could be an indication of the methods used in the past. These tribal people produce considerable quantities of tin without any external help, electric power or chemical agents, enough to make a modern metallurgist, used to high technology, wonder almost in disbelief. Clearly though, the technology practiced has a considerable importance for those studying early smelting practices. The history of this process is poorly known. Back in the 1880s Ball (1881) related the story of a Bastar tribal from the village of Papagudem, who was observed to be wearing a bangle of tin. When questioned as to where the metal had come from, he replied that black sands, resembling gunpowder were dug in his village and smelted there. Thus it is very likely that the present industry is indigenous, and may have a long history. That being said, neither the industry or its products appear in any historical document of any period, and thus is unlikey to have been a significant supplier of metal…The tin content of cassiterite ranges from 74.94% (mean 64.2%), showing that pebbles contain about 70% to 90% of the tin oxide, cassiterite…The ore is localized in gravel beds of the black pebbles of cassiterite which outcrop in stream beds etc. and there are other indicators, in the vegetation. The leaves of the Sarai tree (Shoria robusta) growing on tin-rich ground are often covered in yellow spots, as if suffering from a disease. (The leaves were found to contain 700 ppm of tin on analysis!) Wherever the tribals find concentrations of ore in the top soil, the ground all around the area is dug up and transported to nearby streams, rivers or ponts…The loose gravelly soil containing the tin ore is dug with pick and shovel, and carried to the washing sites in large, shoulder-strung bamboo baskets. The panning or washing of the ore is carrie out using round shallow pans of bamboo. The soil is washed out, leaving the dense casiterite ore at the bottom of the pan…The ore is smelted in small clay shaft furnaces, heating and reducing the ore using charcoal as the fuel…The shft furnaces are square at the base and of brick surmounted by a clay cylindrical shaft…The charcoal acts as both the heating and reducing agent, reducing the black cassiterite mineral into bright, white tin metal…a crude refining is carried out by remelting the metal in an iron pan at about 250 degrees C. The molten tin is then poured into the stone-carved moulds to make square- or rectangular-shaped tin ingots for easy transportation. (Babu, TM, 2003, Advent of the bronze age in the Indian subcontinent in: Craddock, PT and J. Lang, Mining and Metl production through the ages, British Museum, pp.174-180). See: http://bharatkalyan97.blogspot.in/2013/06/asur-metallurgists.html

two late bronze age tin ingots from the harbor of Haifa, Israel contain glyphs used in epigraphs with Indus Writing of Sarasvati civilization!See:http://bharatkalyan97.blogspot.in/2011/11/archaeological-mystery-solved-site-of.htmlThe inscriptions on two pure tin ingots found in a shipwreck in Haifa have been discussed in: Journal of Indo-Judaic Studies, Vol. 1, Number 11 (2010) -- The Bronze Age Writing System of Sarasvati Hieroglyphics as Evidenced by Two “Rosetta Stones” By S. Kalyanaraman (Editor of JIJS: Prof. Nathan Katz)http://www.indojudaic.com/index.php?option=com_contact&view=contact&id=1&Itemid=8 (See embedded document).

Here is a pictorial gallery:

Here is a pictorial gallery:

Panning for cassiterite using bamboo pans in a pond in Orissa. The ore is carried to the water pond or stream for washing in bamboo baskets.

People panning for cassiterite mineral in the remote jungles of central India.

The ore is washed to concentrate the cassiterite mineral using bamboo pans. Base of small brick and mud furnace for smelting tin.

The tin is refined by remelting the pieces recovered from the furnace in an iron pan. The molten tin is poured into stone-carved moulds to make square- or rectangular-ingots.

As the pictorial gallery demonstrates, the entire tin processing industry is a family-based or extended-family-based industry. The historical traditions point to the formation of artisan guilds to exchange surplus cassiterite in trade transactions of the type evidenced by the seals and tablets, tokens and bullae found in the civilization-interaction area of the Bronze Age.

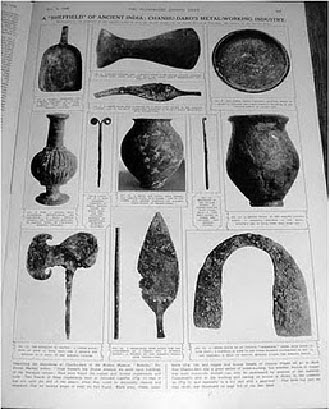

Illustrated London News 1936 - November 21st. A 'Sheffield of Ancient India: Chanhu-Daro's metal working industry 10 X photos of copper knives, spears, razors, axes and dishes.![]()

The words used in the lingua franca of such tin-processing families constitute the words invented to denote the Bronze Age products and artifacts such as tin or zinc or the array of metalware discovered in the Sheffied of the Ancient East, Chanhu-daro as reported in the London News Illustrated by Ernest Mackay.

Validating the Bronze Age Linguistic Doctrine

Hence, the search for the identification of the language Meluhha (mleccha) of Indian sprachbundhas to be carried out in documenting the practices of the types shown in the pictorial gallery of tin processing and from within the cluster of over 8000 semantic clusters of the languages of the Indian sprachbund. This will be a first step in reiterating the Bronze Age Linguistic Doctrine. The directions of borrowings of lexemes from one language to another are secondary features. The fact that such common lexemes related to metallurgy and metalware exist in Indian sprachbund is enough to validate the Bronze Age Linguistic Doctrine.

Validating the Bronze Age Linguistic Doctrine

Hence, the search for the identification of the language Meluhha (mleccha) of Indian sprachbundhas to be carried out in documenting the practices of the types shown in the pictorial gallery of tin processing and from within the cluster of over 8000 semantic clusters of the languages of the Indian sprachbund. This will be a first step in reiterating the Bronze Age Linguistic Doctrine. The directions of borrowings of lexemes from one language to another are secondary features. The fact that such common lexemes related to metallurgy and metalware exist in Indian sprachbund is enough to validate the Bronze Age Linguistic Doctrine.

The doctrine is that Meluhha speech was the vernacular of Indian sprachbund, ancient India of the Bronze Age.

S. Kalyanaraman

Sarasvati Research Center

January 31, 2014